The quality of tungsten wire for textiles weaving gloves is affected by many factors, mainly including:

- Raw material quality

Purity: The main component of tungsten wire is tungsten, and its purity directly affects the performance of the wire. High-purity tungsten can improve the strength, wear resistance and high temperature resistance of tungsten wire.

Alloy composition: If the tungsten wire contains alloy elements, the type and content of the alloy will also affect the comprehensive performance of the tungsten wire.

- Production process

Smelting technology: The smelting process of tungsten ore determines the quality of tungsten powder, which in turn affects the performance of tungsten wire. Advanced smelting technology can better control the purity and consistency of the product.

Wire drawing process: The production of tungsten wire involves drawing tungsten powder into filaments. The control of the wire drawing process (such as drawing speed and temperature) affects the diameter, strength and surface quality of the wire.

Annealing: The annealing process is used to improve the toughness of tungsten wire and remove internal stress. The correct annealing process can improve the processability and stability of the wire.

- Surface treatment

Polishing: The surface finish affects the wear resistance and corrosion resistance of tungsten wire. Good polishing can increase the service life of the wire.

Coating: Certain applications may require specific surface coatings to enhance specific properties of tungsten wire, such as corrosion resistance or wear resistance.

- Environmental control

Production environment: A clean production environment helps avoid surface contamination and defects of tungsten wire. Temperature and humidity control of the environment is also an important factor in the production process.

Equipment maintenance: The accuracy and maintenance status of production equipment can affect the consistency and quality of tungsten wire. Regular maintenance and calibration of equipment can reduce defects in production.

- Quality Control

Testing standards: During the production process, strict quality testing standards and procedures are implemented to effectively identify and correct potential quality problems.

Process control: Continuously monitor key parameters in the production process (such as temperature, tensile force, etc.) to ensure that the product meets the specifications.

- Storage and transportation

Storage conditions: The storage conditions of tungsten wire (such as temperature and humidity) have a certain impact on its quality. Avoiding high humidity and high temperature environments can prevent tungsten wire from corrosion.

Transportation method: During transportation, ensure that the tungsten wire is not damaged or contaminated to maintain its quality.

- Design and application

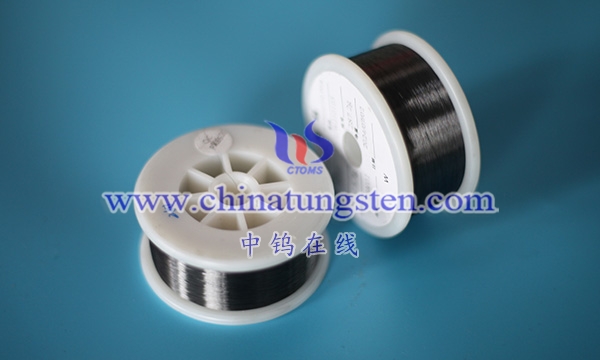

Specification requirements: The design and specifications of tungsten wire (such as diameter, strength, elastic modulus, etc.) should meet the requirements of the final application. Tungsten wire that does not meet the design requirements may perform poorly in actual applications.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595