The determination of the breaking strength of tungsten wire for textiles weaving gloves is a key step in evaluating its performance and reliability under tensile load. The following are commonly used methods for determining breaking strength:

- Tensile Test

Method:

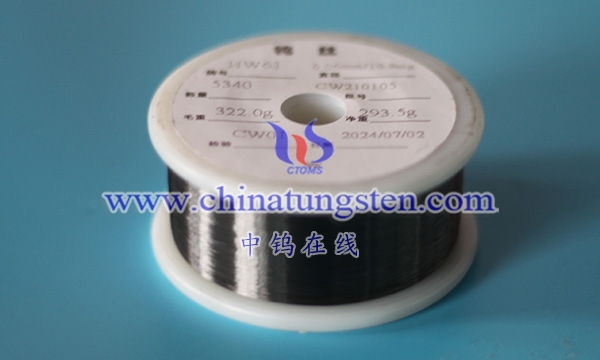

Sample preparation: The tungsten wire is made into a standardized specimen, usually a cylindrical or parallel plate specimen of a certain length and diameter.

Test equipment: Use a tensile testing machine, which can accurately control the tensile force applied to the sample and measure the elongation of the sample.

Test steps: Clamp the tungsten wire sample in the fixture of the testing machine, gradually apply the tensile load, and record the applied force and the elongation of the sample until the sample breaks.

Data analysis: Calculate the breaking strength (σf), which is the maximum load applied at the time of fracture divided by the cross-sectional area of the sample. Fracture strength is usually expressed in megapascals (MPa) or kilograms of force per square millimeter (kgf/mm²).

- Material testing machine

Method:

Sample preparation: Similar to the tensile test, prepare the tungsten wire into a standard sample.

Test equipment: Use a material testing machine, which can accurately measure the mechanical properties of the material, including fracture strength.

Test steps: Perform the test according to the instructions of the testing machine, apply the load and record the data.

Data analysis: Measure the maximum load that the material can withstand before breaking and calculate the fracture strength.

- Stress-strain curve

Method:

Sample preparation: Prepare the tungsten wire into a standard specimen.

Test equipment: Use an electronic universal material testing machine equipped with a force sensor and a displacement sensor.

Test steps: Perform a tensile test, record stress-strain data, and generate a stress-strain curve.

Data analysis: Find the fracture point through the stress-strain curve, and the fracture strength corresponds to the maximum stress value on the curve.

- Fracture Toughness Test

Method:

Sample preparation: Specially prepared samples for the fracture toughness of tungsten wire.

Test equipment: Use a dedicated fracture toughness test equipment.

Test steps: Apply load and record the characteristics of sample fracture.

Data analysis: Analyze fracture toughness and calculate its impact on material properties.

Notes

Sample processing: The surface of the sample should be flat and clean to avoid inaccurate test results due to surface defects.

Test environment: Ambient temperature and humidity may affect the test results, and the test should be carried out under controlled environmental conditions.

Test speed: Control the tensile speed of the testing machine to ensure the accuracy of the data.

Data recording: Make sure to record all relevant data, including load, deformation, and characteristics at fracture.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595