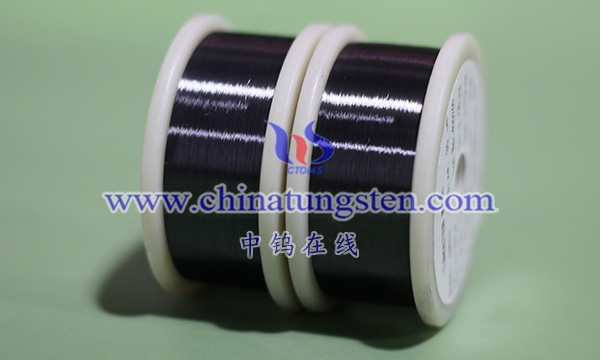

Checking the surface defects of tungsten wire for textiles weaving gloves is a key step to ensure its quality and performance. Common inspection methods include visual inspection, microscopic inspection, surface roughness test, and non-destructive testing. The following are detailed inspection methods and steps:

- Visual inspection

Method:

Tools: magnifying glass or microscope (if higher precision inspection is required).

Steps: In good lighting conditions, use a magnifying glass or naked eyes to inspect the surface of the tungsten wire. Look for obvious defects such as scratches, pits, cracks, uneven colors, etc.

Notes:

Ensure the inspection environment is clean to avoid dust and dirt affecting the inspection results.

Visual inspection is usually used for preliminary screening and a general understanding of defects.

- Microscope inspection

Method:

Tool: metallographic microscope or electron microscope.

Steps: Place the tungsten wire sample under the microscope and magnify its surface structure. Check for tiny cracks, holes, impurities, etc.

Notes:

Microscope inspection can provide a higher resolution surface image, which helps to find defects that are difficult to detect with the naked eye.

Prepare the calibration of the microscope and the cutting and polishing of the sample to ensure the accuracy of the inspection.

- Surface roughness test

Method:

Tool: surface roughness meter.

Steps: Select several test points on the surface of the tungsten wire and use the surface roughness meter to measure its roughness value. Record the roughness data of each point and evaluate its surface finish.

Notes:

Surface roughness testing helps evaluate the processing quality of tungsten wire. Higher roughness values may indicate poor processing or surface defects.

Ensure the calibration of the instrument and the cleanliness of the sample surface before testing.

- Non-destructive testing (NDT)

Method:

Tools: Ultrasonic flaw detector, X-ray flaw detector, magnetic particle detector, etc.

Steps: Select the appropriate non-destructive testing method to detect internal defects. Ultrasonic flaw detectors can detect internal cracks, X-ray flaw detectors can be used to detect internal structural problems, and magnetic particle detectors are suitable for checking surface and near-surface defects.

Notes:

Non-destructive testing can provide detailed information about internal defects of materials and is suitable for applications with high requirements for material integrity.

Select the appropriate testing method according to the specifications and applications of tungsten wire.

- Chemical etching method

Method:

Tools: Etching liquid (such as acid or alkaline solution).

Steps: Immerse the tungsten wire sample in the etching liquid to reveal its surface defects. The etching liquid will react differently to the defects, making them more obvious.

Notes:

Choose appropriate etching liquid and treatment time to avoid excessive corrosion affecting other properties of tungsten wire.

When using chemical etching method, ensure that appropriate safety measures are taken to prevent chemicals from harming operators.

- Surface gloss test

Method:

Tool: gloss meter.

Steps: Measure the gloss of the tungsten wire surface and check whether its gloss is uniform. Uneven gloss may indicate surface defects.

Notes:

Surface gloss test is suitable for checking the smoothness after surface treatment.

It is necessary to ensure that the light in the test environment is stable to avoid external light sources affecting the results.

- Friction test

Method:

Tool: friction test instrument.

Steps: Conduct friction test on tungsten wire through friction test instrument, record friction coefficient and friction loss, and evaluate the effect of surface defects on tungsten wire performance.

Notes:

Friction test can reveal the actual effect of surface defects on tungsten wire performance.

Ensure consistent test conditions and higher reliability of results.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595