The role of tungsten wire in heating elements is mainly reflected in the following aspects:

High temperature stability: Tungsten wire has an extremely high melting point (about 3422°C), which enables it to work stably in high temperature environments. This makes tungsten wire very suitable for use as a heating element, able to maintain stable performance under extreme high temperature conditions.

Good resistance characteristics: Tungsten wire has a high resistivity, which means that it can effectively convert electrical energy into thermal energy when it is powered. Due to the principle of resistive heating, tungsten wire is able to generate stable heat for heating applications.

High temperature thermal conductivity: Tungsten wire is able to maintain good thermal conductivity at high temperatures, which helps to evenly transfer the generated heat to the heating area, ensuring uniformity and efficiency of heating.

Corrosion resistance: Tungsten wire exhibits good corrosion resistance in many high temperature and corrosive environments. This means that it can maintain a long service life under harsh working conditions, thereby improving the reliability and durability of the heating element.

Oxidation resistance: Under high temperature conditions, the surface of tungsten wire is not easily oxidized, which helps to extend its service life. Although tungsten filaments themselves have good oxidation resistance, in practical applications, a protective layer is often applied to the surface of tungsten filaments to further improve their oxidation resistance.

Excellent mechanical strength: Tungsten filaments have high strength and toughness, which makes them less likely to deform or break in high temperature environments, thereby improving the stability and durability of the heating element.

Low thermal expansion coefficient: Tungsten filaments have a low thermal expansion coefficient, that is, the volume of tungsten filaments changes less during heating. This property helps maintain the dimensional stability of the heating element and reduce deformation or damage caused by thermal expansion.

High power density: Tungsten filaments can withstand high power density in a relatively small volume, thereby generating a lot of heat in a compact space. This makes it excel in heating applications that require high power and high temperature.

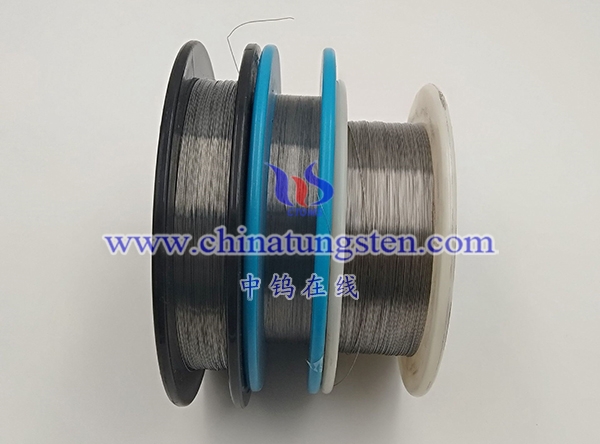

Application examples

Light bulbs: Tungsten filaments are the core heating element of incandescent light bulbs because their high melting point and good resistance properties enable the filaments to emit light at high temperatures.

Electronic equipment: Tungsten filaments are used as heating elements in some high-temperature electronic devices, such as electron tubes and vacuum tubes.

Industrial heating: Tungsten filaments are used in industrial heating applications, such as furnace heating elements and heating elements in high-temperature furnaces.

Laboratory equipment: In high-temperature furnaces and other heating devices in laboratories, tungsten wire is often used for heating elements due to its high temperature stability and corrosion resistance.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595