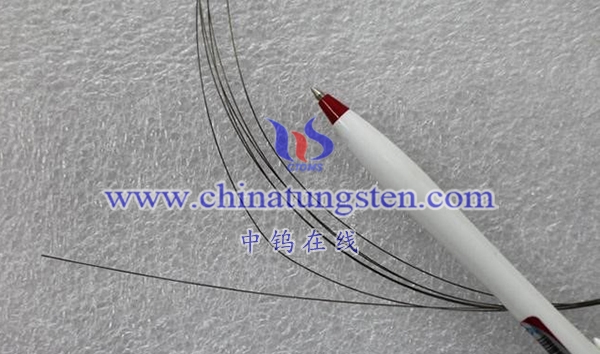

The role of tungsten wire in high-precision screens includes the following aspects:

Improve the strength and durability of the screen: Tungsten wire has extremely high hardness and strength, which allows the screen made of tungsten wire to maintain its shape and performance when facing high-pressure or high-load working environments, reducing deformation and wear.

Enhance the high temperature resistance of the screen: Tungsten wire has a very high melting point (about 3422°C), which allows it to work stably at extremely high temperatures. This makes tungsten wire screens particularly suitable for screening and filtering in high-temperature environments, such as metal smelting and high-temperature chemical reaction processes.

Improve the corrosion resistance of the screen: Tungsten wire has strong corrosion resistance to many chemicals and environmental conditions. This property makes tungsten wire screens perform well when handling corrosive substances and extends the service life of the screen.

Provide high-precision screening capabilities: Tungsten wire has high elasticity and stability, allowing tungsten wire screens to maintain their precise aperture size. In this way, the screen can achieve high-precision screening and is suitable for applications that require strict screening standards.

Reduce deformation of the screen: The high strength and high temperature resistance of tungsten wire make it difficult to deform during operation, thereby maintaining the structural stability and screening efficiency of the screen.

Wear resistance: The wear resistance of tungsten wire makes the screen perform well when handling coarse materials or abrasive materials, and can effectively prevent the loss of the screen during use.

Application Examples

Precision Industrial Screening: In the manufacturing and material processing industries, tungsten wire screens are used for precision screening processes such as ore screening, powder screening, etc. to ensure the accuracy and consistency of the screening effect.

Chemical and Pharmaceutical Industries: Tungsten wire screens are used for filtration and separation in chemical reactions and pharmaceutical processes to maintain the purity and quality of the product.

Aerospace and High-Tech Fields: Tungsten wire screens are used in aerospace and high-tech fields to screen and filter high-value materials such as high-performance alloys and ultra-high-precision components.

Metallurgy and high temperature processing: In the process of metal smelting and high temperature processing, tungsten wire mesh can withstand high temperature and corrosive environment, and is used to handle high temperature molten metal or other substances.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595