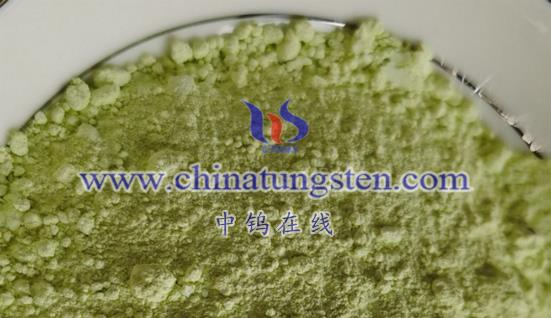

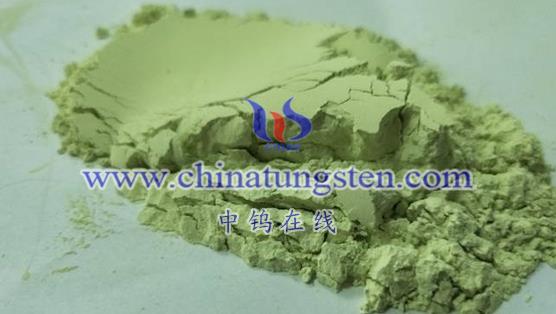

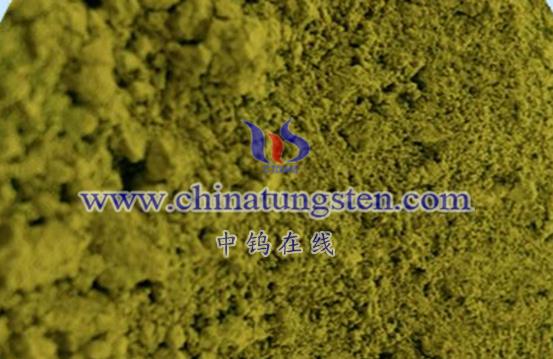

Tungsten oxide (WO3) nanoparticles have several critical applications in the petrochemical industry, primarily due to their excellent catalytic properties, stability, and specific physical and chemical characteristics. Here’s a detailed overview of the various uses of tungsten oxide in petrochemicals:

- Tungsten Oxide Catalysts

- Primary and Secondary Catalysts

Tungsten oxide, especially in its trioxide form (WO3), is a commonly used catalyst in the petrochemical industry due to its large surface area and significant surface effects. It can function as either a primary or a secondary catalyst to promote various chemical reactions. - Catalytic Performance

Tungsten oxide exhibits good catalytic performance in reactions such as hydrogenation, dehydrogenation, oxidation, hydrocarbon isomerization, and alkylation. These reactions are crucial in petrochemical production, where the application of WO3 helps to enhance reaction efficiency, reduce energy consumption, and optimize product quality.

- Selectivity of Tungsten Oxide Catalysts

- High Selectivity

A notable advantage of tungsten oxide catalysts is their high selectivity toward reactions. In complex chemical reaction systems, WO3 can effectively promote the formation of target products while suppressing the generation of by-products. This high selectivity helps to reduce waste, improve raw material utilization, and lower production costs.

- Stability of Tungsten Oxide Catalysts

- Robust Stability

Tungsten oxide catalysts maintain good stability under harsh conditions such as high temperature and pressure. This property allows them to operate continuously and stably in various complex environments within petrochemical production, ensuring consistent production processes.

- Specific Application Examples

- Oil Refining

In oil refining processes, tungsten oxide catalysts can be utilized in catalytic cracking and reforming reactions, enhancing the yield and quality of products like gasoline and diesel. - Chemical Production

In the production of chemicals, WO3 catalysts can facilitate the synthesis of organic compounds such as alcohols, ketones, and acids, providing essential raw materials for the fine chemical sector. - Environmental Applications

Tungsten oxide can also be employed in waste gas and wastewater treatment, where it catalyzes oxidation reactions to convert harmful substances into harmless ones, thereby achieving environmental protection and emission reduction goals.

- Development Trends for Tungsten Oxide Catalysts

- Future Prospects

As the petrochemical industry continues to develop and environmental regulations become more stringent, the application prospects for tungsten oxide catalysts will expand further. Researchers are expected to explore new preparation methods and modification technologies for WO3 catalysts to enhance their catalytic performance, selectivity, and stability to meet higher demands in petrochemical production.

Conclusion

Tungsten oxide nanoparticles hold significant application potential and value in the petrochemical industry. Their exceptional catalytic properties, high selectivity, stability, and specific application examples underscore their important role in petrochemical production processes. As advancements in technology and research continue, the use of tungsten oxide in this field is likely to grow, contributing to more efficient and sustainable petrochemical practices.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595