Here’s an overview of the preparation methods and advantages of nano cesium tungstate dispersion:

- Chemical Solution Method

Steps of the Chemical Solution Method:

- Raw Material Preparation

Dissolve sodium tungstate and cesium nitrate separately in diluted nitric acid solution. - Complexation Reaction

Add complexing agents into both solutions and stir, allowing sodium tungstate and cesium nitrate to form stable complexes in the solution. - Mixing Reaction

Mix the stirred sodium tungstate and cesium nitrate solutions to obtain a cesium tungstate precursor solution. - Drying and Calcination

Dry the precursor solution to remove the solvent and form a solid precursor. Then, calcine at high temperatures to convert the precursor into nano cesium tungstate particles. - Dispersion Treatment

Add the calcined nano cesium tungstate particles into a suitable solvent, and mix with surfactants. Stir and ultrasonically treat the mixture to evenly disperse the particles in the solvent, forming the nano cesium tungstate dispersion.

Advantages of the Chemical Solution Method:

This method allows precise control over the raw material proportions and reaction conditions, yielding nano cesium tungstate particles with specific properties. It is relatively simple, easy to operate, and suitable for large-scale production.

- Direct Dispersion Method

Steps of the Direct Dispersion Method:

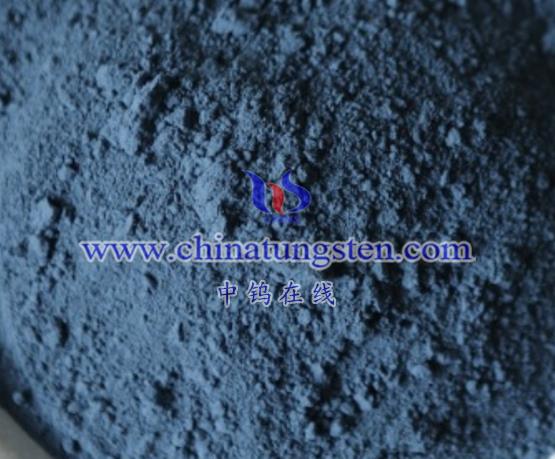

- Raw Material Preparation

Prepare nano cesium tungstate powder, an organic solvent (such as ethanol or acetone), and surfactants (such as sodium dodecyl sulfate). - Preliminary Dispersion

Add the nano cesium tungstate powder directly into the organic solvent and stir to achieve an initial dispersion. - Surface Modification

While stirring, add a suitable amount of surfactant, continuing to stir so that the surfactant coats the surface of the nano cesium tungstate particles. This enhances the dispersion and stability in water or organic solvents. - Ultrasonic Treatment

Ultrasonically treat the mixture, using the cavitation and microjet effects of the ultrasonic waves to further evenly disperse the nano cesium tungstate particles in the solvent. - Filtration and Centrifugation

Filter and centrifuge the ultrasonically treated dispersion to remove impurities and insoluble substances, resulting in a purified nano cesium tungstate dispersion.

Advantages of the Direct Dispersion Method:

This method directly utilizes existing nano cesium tungstate powder for dispersion, without requiring complex chemical reactions. By selecting appropriate surfactants and solvents, dispersions with varying degrees of stability and dispersion can be produced.

- Other Methods

In addition to the two main methods mentioned above, other methods such as sol-gel and hydrothermal methods can also be used to prepare nano cesium tungstate dispersions. Each method has its own advantages and disadvantages. The specific method chosen depends on the desired properties of the nano cesium tungstate particles, production cost, and the scale of production.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595