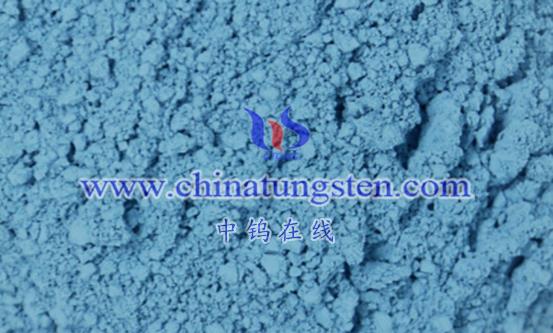

Nano tungsten oxide (WO₃) can be prepared using various methods, each with its own unique advantages and suitable applications. The choice of preparation method can depend on specific requirements and conditions. Here are some common methods for preparing nano tungsten oxide electrode materials:

- Chemical Synthesis Methods

Chemical synthesis is a widely used approach for preparing nano tungsten oxide. This typically includes methods such as precipitation and hydrothermal synthesis.

Precipitation Method

- Process:

- Dissolve ammonium tungstate in distilled water to form an ammonium tungstate solution.

- Add an appropriate amount of ammonia and stir until dissolved, then introduce oxygen.

- Stir and heat the reaction system at a constant temperature (around 70°C).

- Collect and wash the precipitated tungsten oxide to obtain nano tungsten oxide.

- Advantages: The particle size distribution is relatively broad, and the preparation process is simple and easy to control, making it suitable for various applications.

Hydrothermal Method

- Process:

- Dissolve ammonium tungstate in distilled water and add ammonium carbonate, stirring until uniform.

- Pour the solution into a high-pressure reactor, seal the lid, and process under high temperature and pressure (e.g., 180°C and 1.2 MPa).

- Allow the mixture to cool to room temperature, then centrifuge, wash, and dry to obtain nano tungsten oxide.

- Advantages: The particle size is small and has a narrow distribution, with good roundness and dispersion, making it a method that allows for easy control of preparation parameters.

- High-Energy Ball Milling Method

High-energy ball milling is an effective method for preparing nano materials. It involves grinding particles using a high-energy ball mill, leading to strain and plastic deformation during the process.

- Process:

- Mix tungsten powder with ammonium carbonate and place it in a ball mill.

- Separate the milled mixture through a sieve to obtain nano tungsten oxide.

- Advantages: This method produces nano tungsten oxide with small and uniformly distributed particle sizes. The desired shape and characteristics can be achieved by controlling the preparation parameters.

- Other Methods

In addition to the aforementioned methods, several other techniques can also be used to prepare nano tungsten oxide electrode materials, including:

- Template Method: Utilizes a template to guide the formation of the desired structure.

- Calcination of Mesoporous Precursors: Involves heating mesoporous materials to create nano tungsten oxide.

- Organic Solution Method: Uses organic solvents to facilitate the synthesis of nano tungsten oxide.

- High-Temperature Oxidation Method: Involves oxidizing tungsten powder at high temperatures.

- Infrared Heating Oxidation Method: Utilizes infrared heating for the oxidation process.

These alternative methods may present challenges such as complexity of the process and lower production efficiency.

Conclusion

The various preparation methods for nano tungsten oxide electrode materials offer a range of advantages and applications. As technology advances, new methods will continue to emerge, providing more options for the preparation and application of nano tungsten oxide in energy storage and other fields.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595