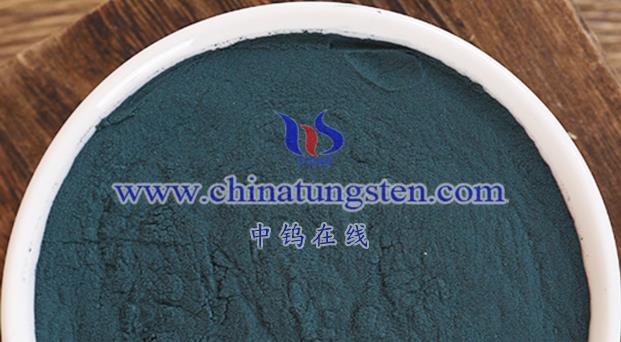

Impurity elements in nano tungsten oxide can significantly impact its properties, often arising from raw materials, contamination during preparation, or inadequate control over reaction conditions. Here are the specific effects of these impurities on nano tungsten oxide performance:

- Effect on Purity

- The presence of impurity elements reduces the purity of nano tungsten oxide, directly affecting its electrical, thermal, and mechanical properties. Particularly, high-temperature stability and oxidation resistance may significantly decrease due to impurity elements acting as defect centers. These impurities disrupt the crystal structure and electronic configuration, thereby weakening the intrinsic properties of the material.

- Effect on Particle Size and Distribution

- Impurity elements can substantially influence the particle size and distribution of nano tungsten oxide. Certain impurities might promote or inhibit crystal growth, leading to particle size differences. For instance, elements like iron, copper, nickel, or cobalt may encourage WO₃-x crystal growth, resulting in larger particle sizes, whereas elements like manganese, chromium, or zinc may inhibit growth, resulting in smaller particles. Variations in particle size and distribution affect characteristics such as surface area and pore structure, which in turn impact catalytic and adsorption properties.

- Effect on Oxidation State

- Impurities can also alter the oxidation state of nano tungsten oxide, thereby affecting its chemical and catalytic properties. Some impurities may act as reducing or oxidizing agents, reacting with nano tungsten oxide and changing its oxidation state. This can modify the activity and selectivity of nano tungsten oxide in catalytic reactions, potentially impacting its efficiency and effectiveness in various applications.

- Effect on Thermal Expansion Coefficient

- Impurity elements can affect the thermal expansion coefficient of nano tungsten oxide, which impacts dimensional stability and thermal stress distribution at high temperatures. A high concentration of impurities may cause a mismatch in thermal expansion coefficients between the nano tungsten oxide and the matrix material, leading to thermal stress concentration and crack propagation, which compromises structural integrity under high-temperature conditions.

- Other Effects

- In addition to the above effects, impurity elements may also impact optical and magnetic properties. For instance, certain impurities may serve as luminescence or magnetic centers, affecting the luminescent and magnetic characteristics of nano tungsten oxide.

Given these extensive impacts, to ensure high performance and purity of nano tungsten oxide, it is crucial to rigorously control preparation parameters and conditions, use high-purity raw materials, and employ advanced production techniques to minimize impurity introduction and contamination. Additionally, strict quality testing and purification are essential to confirm that nano tungsten oxide meets the required standards for various applications.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595