Blue Tungsten Oxide (BTO) and Violet Tungsten Oxide (VTO or TVO) differ in several ways. Here is a detailed comparison:

- Chemical Composition and Structure

Blue Tungsten Oxide

Composed of 20 tungsten atoms and 58 oxygen atoms, with a chemical formula of W20O58 or approximately WO2.90. It is a mixture primarily made up of ammonium tungsten bronze (ATB), hydrogen tungsten bronze, β-tungsten oxide, and γ-tungsten oxide.

Violet Tungsten Oxide

Composed of 18 tungsten atoms and 49 oxygen atoms, with a chemical formula of W18O49 or approximately WO2.72. It appears as a fine purple powdery crystal with a unique crystal structure.

- Physical Properties

Color and Form

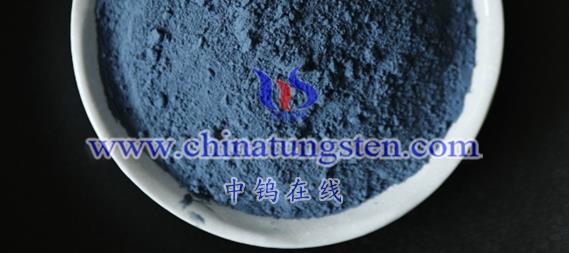

Blue tungsten oxide is a light or dark blue powder, whereas violet tungsten oxide is a purple or bluish-purple powder in tiny crystal form.

Grain Size and Morphology

Under identical raw material and manufacturing conditions, blue tungsten oxide has more defined edges, larger particle size, and fewer fractures compared to violet tungsten oxide. Violet tungsten oxide particles tend to have a rod- or flake-like morphology, while blue tungsten oxide’s morphology may vary depending on its specific composition.

Density

The measured density of blue tungsten oxide is approximately 7.15g/cm³, with an X-ray density of about 7.16g/cm³. In contrast, violet tungsten oxide has a measured density between 7.7 and 7.9g/cm³, with an X-ray density of about 7.78g/cm³.

- Applications and Fields of Use

Common Uses

Both types can be used to produce tungsten powder and tungsten salts and share characteristics such as a high surface area, high chemical reactivity, strong absorption of electromagnetic waves (including UV and near-infrared), low bulk density, high oxidation potential, low reduction potential, and good photoelectric properties and gas sensitivity.

Specific Uses

In addition to producing tungsten powder and tungsten salts, blue tungsten oxide can also be used as an oxygen scavenger in vacuum equipment, a color-changing material in smart windows, and a gas-sensitive material. Due to its unique crystal structure and properties, violet tungsten oxide is especially suited for producing ultrafine and nano tungsten powders and can be used to make fine tungsten carbide powder. It also shows potential for applications in photocatalysis and gas sensor technology.

- Production Processes

The production processes for both materials are similar and include ammonium paratungstate hydrogen reduction, closed calcination of tungsten trioxide, and direct synthesis methods. However, due to the different ratios of tungsten to oxygen atoms in blue and violet tungsten oxide, the parameters required in the production process (such as concentration and flow rate of reducing gas) vary.

In summary, blue and violet tungsten oxides differ significantly in chemical composition, physical properties, applications, and production processes. These differences give each type unique advantages and applications in various fields.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595