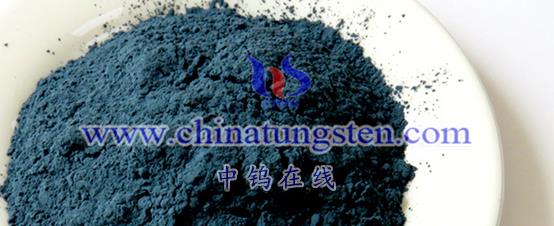

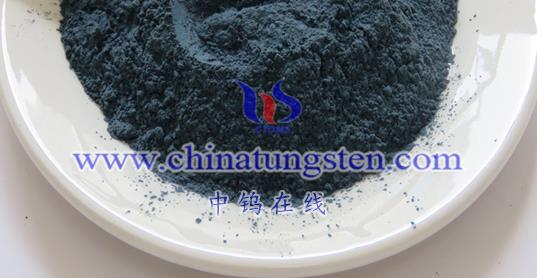

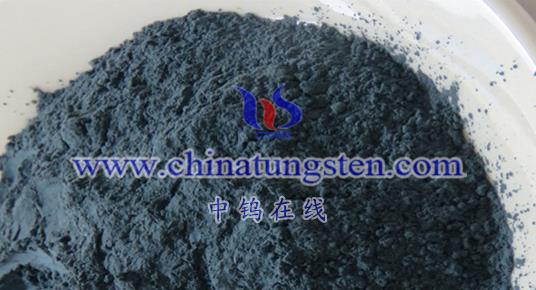

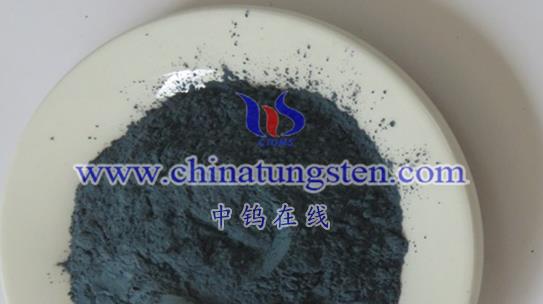

Defect-state tungsten trioxide (WO₃₋ₓ), also known as tungsten trioxide with oxygen vacancies, exhibits unique properties in optical, electrical, and catalytic applications. Various methods are used to produce WO₃₋ₓ, each with distinct steps and advantages. Below are some commonly used preparation methods:

- Vacuum Thermal Evaporation Coating Method

This method is mainly for producing thin films of defect-state tungsten trioxide with stable structure and broad-spectrum response.

Procedure:

- Connect a tungsten source to the evaporation electrode in a vacuum thermal evaporation machine and place a substrate at a set distance from the tungsten source.

- Evacuate the chamber, introduce oxygen and inert gas, and maintain a stable pressure.

- Heat the tungsten boat to a high temperature, causing it to oxidize and sublimate, forming a vapor-phase tungsten oxide layer that deposits on the substrate.

- Interrupt the oxygen supply to induce high-temperature, low-oxygen processing, creating oxygen vacancies and forming the defect-state tungsten trioxide.

This method allows precise control over process parameters such as substrate distance, chamber pressure, and temperature, enabling the production of defect-state WO₃ films with high crystallinity and structural stability.

- Hydrothermal Synthesis

The hydrothermal method involves dissolving and recrystallizing reactants in a high-pressure environment, often with a reducing agent like glucose to introduce oxygen vacancies.

Procedure:

- Dissolve tungsten precursors, surface modifiers, and reducing agents in water, stirring until completely mixed.

- Adjust the pH to an appropriate range.

- Place the solution in a reactor, where it undergoes hydrothermal reaction under high temperature and pressure.

- After the reaction, separate, wash, dry, and calcine the product to obtain defect-state WO₃.

This method is cost-effective and allows for control over oxygen vacancy concentration by adjusting the amount of reducing agent and calcination parameters.

- Additional Methods

Other methods include precipitation, sol-gel, microemulsion, gas-liquid reaction, and template-assisted methods, each with its own advantages and challenges.

- Precipitation Method: Produces powders with high crystallinity but may cause particle agglomeration.

- Sol-Gel Method: Yields uniformly small particles, though controlling the sol-gel transition can be challenging.

- Template-Assisted Method: Allows for precise control over morphology and particle size, though templates can be costly.

Each method offers specific benefits, and the choice depends on application requirements and available laboratory conditions. Process parameters must often be optimized for the desired performance in defect-state tungsten trioxide materials.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595