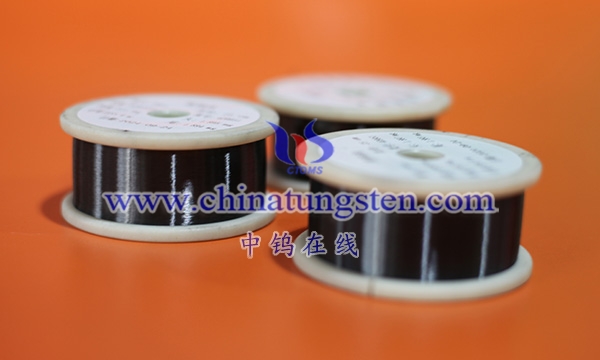

The application of tungsten wire in cable protection has its uniqueness and certain limitations. The following is a detailed analysis of whether tungsten wire is suitable for cable protection:

Advantages:

High melting point and corrosion resistance: Tungsten wire has an extremely high melting point (up to 3422℃) and excellent corrosion resistance. This allows tungsten wire to maintain stable performance in high temperature and corrosive environments. For cables that need to work under extreme conditions, tungsten wire may be an ideal choice.

Good conductivity: Tungsten wire has good conductivity, which means that using tungsten wire in cables can ensure the effective transmission of current and reduce energy loss.

Disadvantages and limitations:

High cost: The price of tungsten wire is much higher than that of common conductor materials such as copper and aluminum, which will increase the production cost of cables. Therefore, when considering the use of tungsten wire as a cable material, it is necessary to weigh the cost-effectiveness.

Difficulty in processing: Tungsten wire is relatively difficult to process, which may increase the complexity and time cost of cable manufacturing.

Brittleness and weight: Tungsten wire is relatively fragile and easy to break when bent, which limits its application in flexible cables. In addition, the density of tungsten wire is higher than that of common conductor materials such as copper and aluminum, which will increase the weight of the cable and is not conducive to the laying and use of the cable.

Poor resistance to current yield: Although tungsten wire has good conductivity, its resistance to current yield is poor. When the current passing through the device is greater than the rated current, the tungsten wire may react quickly, causing the fuse box to trip or fuse. Although this can protect the equipment and lines to a certain extent, it also limits its application in situations where it needs to withstand large current shocks.

Comprehensive consideration: As a conductive material, tungsten wire has certain application potential in cable protection, especially in harsh environments such as high temperature and corrosion. However, due to its high cost, difficulty in processing, brittleness and weight, the application of tungsten wire in cable protection is subject to certain restrictions. In practical applications, it is necessary to weigh the pros and cons according to specific scenarios and needs and choose the most suitable cable material.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595