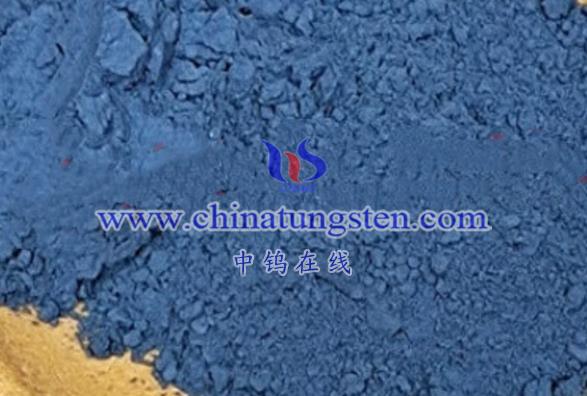

Vanadium-doped single-crystal tungsten oxide shows unique advantages and disadvantages in the field of energy storage. Here is a detailed analysis:

Advantages

- Enhanced Electrochemical Performance

- Multi-Valent Properties of Vanadium: Vanadium’s ability to exhibit multiple oxidation states (+2 to +5) enables multi-electron transfer reactions during energy storage, leading to higher specific capacity and energy density.

- Improved Ion Diffusion and Structural Stability: Vanadium doping enhances ion transport rates and stabilizes the tungsten oxide structure, improving cycling stability and extending material lifespan.

- Optimized Electrochromic Performance

- Unique Electrochromic Behavior: Vanadium-doped tungsten oxide nanowires demonstrate remarkable electrochromic properties. Vanadium ions facilitate charge transfer under applied voltage, enabling color changes. This property is valuable for applications like smart windows and light modulation devices.

- Advantages of Single-Crystal Structure

- Efficient Electron and Ion Transport: The ordered crystal structure with minimal grain boundaries enhances conductivity and ion diffusion rates.

- Improved Stability: Single-crystal structures reduce performance degradation during charge-discharge cycles, increasing cycle stability and longevity.

- High Specific Surface Area

- Nanostructure Benefits: The nano-scale vanadium-doped single-crystal tungsten oxide has a large specific surface area, increasing contact with the electrolyte and improving storage capacity and device performance.

- Environmentally Friendly

- Inorganic Material: Compared to organic energy storage materials, vanadium-doped tungsten oxide is more environmentally friendly and aligns with sustainable development goals.

Disadvantages

- High Cost

- Expense of Vanadium: As a rare metal, vanadium is relatively expensive, increasing the overall cost of vanadium-doped tungsten oxide materials. This cost factor may limit its large-scale commercial applications.

- Low Technological Maturity

- Early Stage Development: While promising results have been achieved in laboratories and pilot projects, the technology is not yet fully mature. Further research is required to enhance performance, reliability, and scalability.

- Complex Manufacturing Process

- Precision Requirements: Producing high-purity, homogeneously doped single-crystal tungsten oxide involves complex processes and stringent control of conditions, which increases production costs and affects quality consistency.

- Incomplete Industrial Chain

- Supply Chain Challenges: The industrial chain for vanadium-doped single-crystal tungsten oxide is underdeveloped, with bottlenecks in raw material supply, production processes, and equipment recycling. These challenges hinder large-scale industrial adoption.

Conclusion

Vanadium-doped single-crystal tungsten oxide offers significant advantages, such as enhanced electrochemical and electrochromic performance, structural benefits, and environmental compatibility. However, it also faces challenges, including high costs, low technological maturity, complex fabrication, and an incomplete industrial chain. Future research should aim to address these issues to accelerate its adoption in energy storage and related fields.

More details of tungsten oxide product, please visit website: tungsten-oxide.com

Please contact CHINATUNGSTEN for inquiry and order of tungsten oxide:

Email: sales@chinatungsten.com

Tel.: 86 592 5129595