The role of tungsten wire in electromagnetic compatibility (EMC) equipment is not directly aimed at improving electromagnetic compatibility, but based on its physical and chemical properties, it plays a specific role in related equipment. The following is a detailed explanation of the possible role of tungsten wire in electromagnetic compatibility equipment:

- As an electrode material

High melting point and high temperature resistance:

The melting point of tungsten wire is as high as 3422℃, which is one of the highest melting points of all metals.

In high-voltage electrodes, tungsten wire is not easy to ablate and can provide current stably.

In arc tubes, tungsten wire can maintain the long life and stability of electrodes at high currents due to its high melting point and good electronic discharge performance.

Application examples:

In electromagnetic compatibility test equipment, such as high-voltage test equipment, tungsten wire is often used as an electrode material.

Tungsten wire is also used as an electrode in some types of discharge tubes, which may be used in electromagnetic compatibility testing or protection circuits.

- As a hot cathode material

Thermal emission performance:

Tungsten wire can withstand high temperatures, so it is often used as a hot cathode material.

In electronic vacuum equipment, such as electron microscopes, television picture tubes and electron tubes, tungsten wire hot cathodes can withstand high-temperature electron emission and have the characteristics of long life, stability and high efficiency.

Application examples:

In some electromagnetic compatibility equipment, such as electromagnetic shielding test equipment, electron tubes or similar equipment may be required, and tungsten wire hot cathodes come in handy.

- Indirect impact on electromagnetic compatibility

Improve equipment stability:

Tungsten wire can improve the overall stability of the equipment due to its excellent physical and chemical properties.

Stable equipment is more likely to meet the requirements of electromagnetic compatibility, because electromagnetic compatibility is often closely related to the stability and reliability of the equipment.

Reduce electromagnetic interference:

Although tungsten wire itself does not directly reduce electromagnetic interference, its stable application in equipment helps to reduce electromagnetic interference caused by equipment failure or instability.

- Other applications

Resistor and inductor components:

Tungsten wire can also be used to manufacture resistor and inductor components, which may play the role of current limiting, voltage reduction or filtering in electromagnetic compatibility equipment.

Special uses:

In some special electromagnetic compatibility equipment, such as test equipment for extreme environments, tungsten wire may be used as a specific structural material or connection material due to its high melting point and high strength.

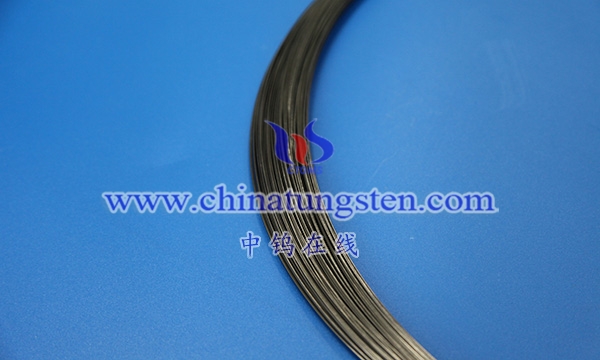

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595