Tungsten wire can be used in equipment that withstands ultrasonic vibration, but the specific application effect needs to be determined according to the specific requirements of the equipment and the performance characteristics of tungsten wire. The following is a detailed analysis of this issue:

- Performance characteristics of tungsten wire

High melting point and high strength: The melting point of tungsten wire is as high as 3410℃, and it has high strength, which makes it have excellent performance in high temperature and high stress environments.

Good conductivity: Tungsten wire is a good conductor with excellent conductivity, which makes it advantageous in applications that require conductivity.

Corrosion resistance: Tungsten wire has good corrosion resistance to a variety of chemicals and can maintain stable performance in harsh chemical environments.

- Requirements for ultrasonic vibration equipment

Vibration stability: Ultrasonic vibration equipment requires stable vibration output to ensure the normal operation and processing effect of the equipment.

Material vibration resistance: The materials in the equipment need to be able to withstand the high-frequency vibration and stress caused by ultrasonic vibration to avoid damage or failure.

Conductive properties: In some ultrasonic vibration equipment, the material needs to have good conductivity to ensure the normal transmission of current.

- Application of tungsten wire in ultrasonic vibration equipment

Vibration element: Tungsten wire can be used as one of the vibration elements of ultrasonic vibration equipment due to its high strength and good conductivity. During the vibration process, tungsten wire can maintain stable vibration output and is not easy to be damaged.

Conductive element: In ultrasonic vibration equipment that requires conductive properties, tungsten wire can be used as a conductive element. Its excellent conductive properties can ensure the normal transmission of current and improve the operating efficiency of the equipment.

- Precautions

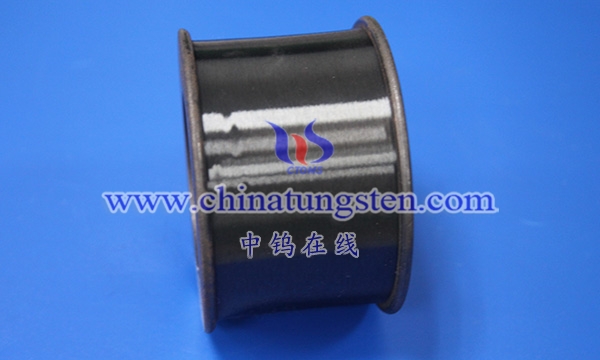

Choose suitable tungsten wire: According to the specific requirements of the ultrasonic vibration equipment and the performance characteristics of tungsten wire, select the appropriate tungsten wire specifications and purity grades.

Optimize equipment design: In the process of equipment design, the performance characteristics and vibration requirements of tungsten wire need to be fully considered to ensure the normal operation and processing effect of the equipment.

Regular maintenance inspection: During use, the equipment needs to be regularly maintained and inspected to promptly discover and deal with potential problems to ensure the long-term stable operation of the equipment.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595