The high density of tungsten alloy has a significant impact on radiation shielding performance. Its core function lies in the ability of high-density materials to more effectively absorb and attenuate radiation energy. Below is a detailed analysis:

- Basic Principles of Radiation Shielding

- The effectiveness of radiation shielding primarily depends on the material’s linear attenuation coefficient, which is directly related to the material’s density.

- In high-density materials, atoms are arranged more closely together, meaning there are more atoms per unit volume. This increases the probability of radiation interacting with atoms.

- Tungsten alloy has a density range of 16–19 g/cm³, which is higher than lead (approximately 11.34 g/cm³), making its shielding effect significantly better than that of lead.

- Shielding Effectiveness for Different Types of Radiation

- X-rays and Gamma Rays: These high-energy electromagnetic radiations interact with the material’s atomic nucleus or electron cloud and are absorbed or scattered through the photoelectric effect, Compton scattering, and pair production.

- Tungsten has a high atomic number (74) and density, enabling it to effectively absorb high-energy radiation and significantly reduce penetration.

- Neutron Radiation: Although tungsten alloy is less effective at shielding neutrons compared to light elements (such as polyethylene), it can form composite shields when combined with other materials (such as boron-containing substances).

- X-rays and Gamma Rays: These high-energy electromagnetic radiations interact with the material’s atomic nucleus or electron cloud and are absorbed or scattered through the photoelectric effect, Compton scattering, and pair production.

- Improving Shielding Efficiency

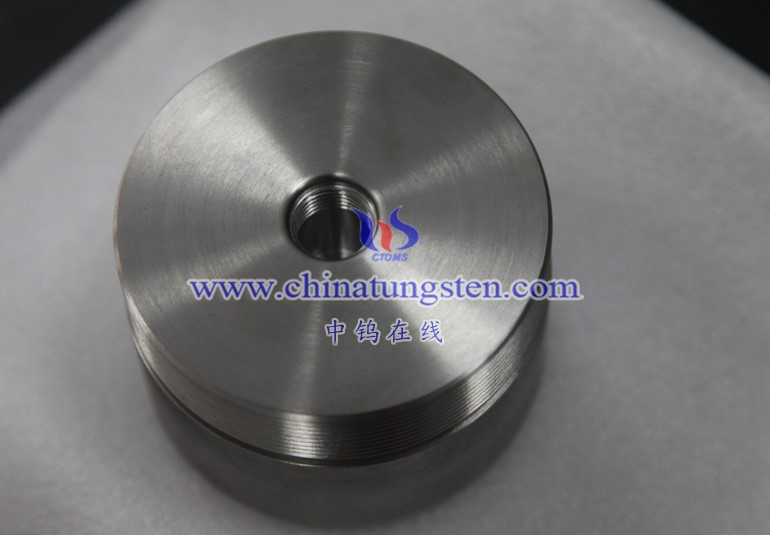

- For the same shielding effectiveness, tungsten alloy components can be designed to be thinner and more compact.

- For example, medical shielding devices made from tungsten alloy are lighter, occupy less space, and provide better radiation protection than lead shielding components.

- Tungsten alloy’s high density makes it especially suitable for devices that require portability or have limited space, such as mobile X-ray machines or nuclear medicine shielding containers.

- For the same shielding effectiveness, tungsten alloy components can be designed to be thinner and more compact.

- Optimizing Shielding Design

- The high density of tungsten alloy allows shielding components to adopt more complex shape designs. This is particularly effective in multi-angle, layered protection scenarios, where it can more efficiently absorb radiation from multiple directions.

- In high-energy radiation environments (such as radiotherapy equipment), tungsten alloy collimators rely on its density to provide precise control of radiation beam paths, minimizing radiation exposure to healthy tissues.

- Advantages in Practical Applications

- Reducing Radiation Leakage: High-density materials significantly reduce radiation penetration, forming more reliable protective barriers around the outer walls of medical equipment and radiation sources.

- Extending Service Life: Due to the high hardness of tungsten alloy, shielding components are less likely to wear out in high-dose radiation environments, maintaining stable protective performance over time.

Conclusion The high density of tungsten alloy is key to its radiation shielding performance. By increasing the probability of radiation interacting with the material, it greatly enhances shielding effectiveness while enabling smaller, lighter designs. This provides reliable and efficient radiation protection in modern medical equipment.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595