Tungsten alloy shielding parts and lead shielding parts have a range of advantages and disadvantages when compared. Below is a comparison of the two materials in terms of radiation protection:

Advantages:

- Radiation Shielding Performance

- Tungsten Alloy:

- Higher Density and Atomic Number: Tungsten alloy has a slightly lower density and atomic number (74) than lead (82), but its shielding effectiveness remains excellent. It can effectively absorb high-energy radiation such as X-rays and gamma rays. As a result, tungsten alloy is often chosen in environments that require high-efficiency radiation protection.

- Thinner Shielding Thickness: The higher density of tungsten alloy allows it to provide similar radiation shielding effects with a thinner material thickness, which is particularly beneficial in space-constrained environments.

- Lead:

- Known Radiation Protection Performance: Lead has a high atomic number (82), which allows it to effectively attenuate X-rays and gamma rays, especially in traditional medical radiation protection applications. Its high density also contributes to its effective radiation shielding performance.

- Tungsten Alloy:

- Environmental and Health Impacts

- Tungsten Alloy:

- Non-toxic: Tungsten alloy is relatively eco-friendly and does not contain harmful heavy metals, especially lead. Over long-term use, tungsten alloy does not release toxic substances or cause environmental pollution, aligning with current environmental protection requirements.

- Lead:

- Toxic: Lead is a toxic heavy metal, and prolonged exposure can adversely affect human health. Lead dust, vapors, or discarded lead materials, if improperly handled, can harm the environment and health.

- Tungsten Alloy:

- Mechanical Properties

- Tungsten Alloy:

- Higher Strength and High-Temperature Resistance: Tungsten alloy has very high hardness and strength, making it capable of withstanding higher temperatures. This gives it an edge in specialized environments (e.g., high radiation and high-temperature settings). Its mechanical properties make it more suitable for devices requiring extra strength and durability.

- Lead:

- Softer Nature: Lead is softer and more prone to deformation, which can lead to wear and degradation over time. For applications requiring high mechanical performance, lead may not be as durable as tungsten alloy.

- Tungsten Alloy:

- Processing and Use

- Tungsten Alloy:

- Difficult to Process: Due to its high hardness, tungsten alloy is more complex and costly to process. Special equipment and techniques are required.

- Lead:

- Easy to Process: Lead’s softness makes it easier to process, allowing for low-cost molding and simple equipment, making it ideal for mass production.

- Tungsten Alloy:

- Volume and Weight

- Tungsten Alloy:

- More Compact: Tungsten alloy shielding parts, while providing the same shielding effect, are more compact and lightweight than lead. This reduces the size and weight of the equipment, which is particularly important in space-constrained environments.

- Lead:

- Heavier: While lead also has a high density, to provide the same shielding effect, lead shielding parts are larger and heavier. This may affect the mobility and ease of use of the equipment.

- Tungsten Alloy:

Disadvantages:

- Cost

- Tungsten Alloy:

- Higher Cost: Tungsten alloy materials are more expensive than lead due to tungsten being a rare metal, the complex processing involved, and the relatively intricate production process. The initial investment cost for tungsten alloy is higher, which could pose challenges for budget-limited projects.

- Lead:

- Lower Cost: Lead is less expensive, especially for large-scale production. This gives lead shielding parts a clear economic advantage, making lead a more cost-effective choice in many applications.

- Tungsten Alloy:

- Processing Difficulty

- Tungsten Alloy:

- Higher Processing Difficulty: Tungsten alloy is harder and difficult to process into complex shapes or thin layers. This increases manufacturing costs and processing time, and requires higher technical skills.

- Lead:

- Easy to Process: As a soft metal, lead is easier to process, especially when manufacturing large-area shielding parts. It is simpler and more efficient compared to tungsten alloy.

- Tungsten Alloy:

- Impact on Image Quality

- Tungsten Alloy:

- Possible Impact on Image Quality: Due to tungsten alloy’s high density and strong radiation absorption capability, it may affect image quality in some high-precision medical devices, especially in low-energy radiation applications. To compensate, additional exposure or adjustments to other parameters might be necessary.

- Lead:

- Minimal Impact on Image Quality: Lead is easier to adapt to various medical imaging devices and does not impact imaging details as tungsten alloy does. Lead shielding parts typically perform better in terms of image quality, especially in traditional X-ray applications.

- Tungsten Alloy:

Summary:

- Advantages of Tungsten Alloy:

- Highly efficient radiation shielding performance with a thinner shielding thickness

- Non-toxic, environmentally friendly

- Higher strength, high-temperature resistance, and mechanical properties

- Smaller volume and lighter weight, suitable for space-constrained environments

- Disadvantages of Tungsten Alloy:

- Higher cost and processing difficulty

- May have a greater impact on image quality

- Advantages of Lead:

- Lower cost, easy to process

- Good radiation protection performance, widely used in traditional medical devices

- Minimal impact on image quality

- Disadvantages of Lead:

- Toxic and not environmentally friendly

- Softer, with poor mechanical properties and prone to wear

- Heavier, bulkier, not suitable for applications requiring compact designs

In general, tungsten alloy is suitable for high-end applications with strict space and weight requirements, especially where higher mechanical performance and environmental considerations are important. Lead, on the other hand, remains a cost-effective and efficient radiation protection material for many traditional applications.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

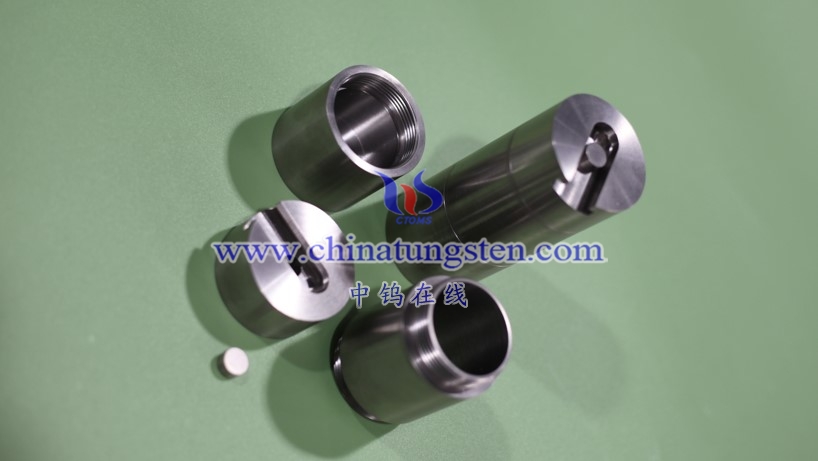

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595