Although tungsten alloy medical shielding parts possess excellent radiation protection capabilities, certain storage conditions must still be followed to ensure their long-term performance and prevent damage. Below are the main storage requirements for tungsten alloy medical shielding parts:

- Temperature Control Tungsten alloys have a high melting point and good thermal stability, but extreme temperatures can affect the material’s long-term stability. To maintain the physical and mechanical properties of tungsten alloys, the following measures should be taken:

- Avoid High Temperature Storage: Although tungsten alloys can withstand high temperatures, extreme heat can accelerate material aging or cause oxidation on the metal surface. The ideal storage temperature should be room temperature to avoid drastic temperature fluctuations.

- Avoid Excessive Low Temperature: Extremely low temperatures may increase the brittleness of the alloy, especially under impact or pressure. While tungsten alloys typically have high strength and hardness at low temperatures, to prevent potential cracking or damage, the storage temperature should be kept within a reasonable range.

- Humidity Control High humidity can lead to rusting or corrosion of the surface of tungsten alloys, affecting their performance. To avoid this, the following measures should be taken:

- Maintain a Dry Environment: Tungsten alloy shielding parts should be stored in a dry environment, avoiding exposure to humid air, particularly in high-humidity conditions. Excessive humidity can cause oxidation, which may affect the alloy’s appearance and protective properties.

- Use Moisture-Proof Packaging: During storage and transport, moisture-proof packaging materials (such as desiccants or sealed bags) can be used to control humidity and prevent moisture exposure on the metal surface.

- Avoid Direct Sunlight Exposure Prolonged exposure to direct sunlight, especially in high-temperature environments, can cause the material to expand and may alter its physical properties. To ensure the quality of tungsten alloy shielding parts, they should be stored away from direct sunlight:

- Avoid UV Damage: Ultraviolet rays from sunlight may damage some surface coatings or packaging materials, particularly with prolonged exposure. To maintain the integrity of tungsten alloy shielding parts, it’s best to store them in a cool place or use opaque storage containers.

- Avoid Mechanical Damage While tungsten alloys are hard, they still need protection from severe impacts or mechanical pressure to prevent cracking or damage:

- Prevent Compression: When storing tungsten alloy shielding parts, ensure that they are not excessively compressed or stacked. Ensure there is adequate space between items to avoid deformation or surface damage due to compression or collision.

- Use Proper Support and Packaging: Soft padding materials, foam, or wooden boxes can be used as support materials to ensure that shielding parts are not subjected to external force during storage.

- Prevent Oxidation Tungsten alloys have strong corrosion resistance, but if the alloy surface has coatings or micro-cracks, it may be susceptible to oxidation, especially in high-humidity or high-temperature environments. Therefore, the following measures should be taken during storage:

- Avoid Contact with Corrosive Substances: Tungsten alloy shielding parts should be kept away from corrosive chemicals (such as acids or alkalis), which may negatively affect the alloy surface.

- Use Anti-Oxidation Coatings: Some tungsten alloy shielding parts may have special anti-oxidation coatings, such as aluminum or titanium coatings. During storage, care should be taken not to scratch or damage these coatings to prevent oxidation.

- Avoid Strong Magnetic Fields Tungsten alloys have low magnetism, but storage environments should avoid strong magnetic fields, especially in medical environments where shielding parts are used. Strong magnetic fields may affect certain special materials or electronic devices. Although tungsten alloys are not easily affected by magnetic fields, it’s still advisable to avoid them when possible.

- Cleaning and Inspection Before storage, tungsten alloy shielding parts should be cleaned properly to remove surface dirt, oil, or other impurities. Regular inspections should be carried out to ensure that no oxidation or cracks have occurred on the surface, allowing for the early detection and handling of potential quality issues.

- Proper Storage Location Tungsten alloy shielding parts should be stored in dedicated storage areas, away from areas that may cause contamination or damage. For example:

- Avoid Proximity to Heat Sources: Keep parts away from heat sources such as heating devices to prevent temperature-induced changes in material performance.

- Keep Away from Flammable and Explosive Materials: Prevent fire hazards or other accidents under special conditions.

Summary: The storage conditions for tungsten alloy medical shielding parts should focus on factors like temperature, humidity, mechanical damage, and oxidation protection. To ensure the shielding parts maintain their excellent performance during long-term storage, a dry, cool environment should be chosen, avoiding extreme temperature fluctuations, and appropriate packaging and protection measures should be taken. Regular inspections and maintenance of storage conditions help ensure that tungsten alloy shielding parts remain in optimal condition, ready for use.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

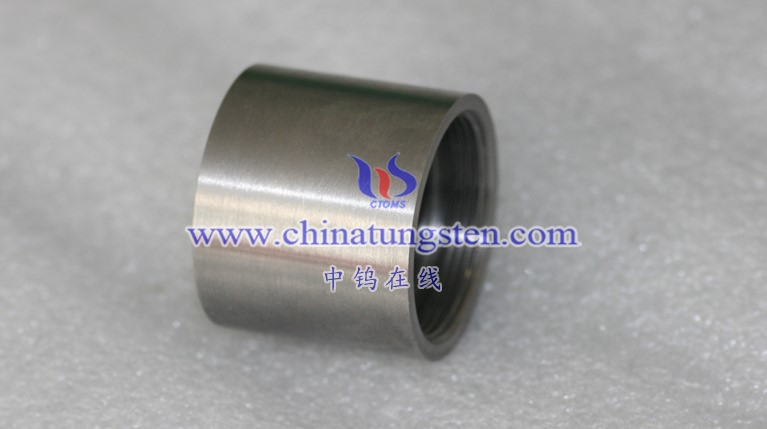

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595