Yes, the design of tungsten alloy shielding parts must highly consider user safety, especially in medical equipment, as it directly impacts the safety of both operators and patients. While tungsten alloy shielding parts provide radiation protection, the design must also take into account several safety factors to ensure that no additional hazards are introduced during the equipment’s use. Below are key safety aspects that need special attention in the design:

- Preventing Radiation Leakage The primary function of tungsten alloy shielding parts is to block radiation, particularly high-energy radiation such as X-rays and γ-rays. During the design, it is essential to ensure that the shielding parts fully cover the radiation source and prevent any leakage of radiation outside the equipment. Improper design or installation could lead to radiation leakage, endangering the health of operators, patients, or surrounding personnel.

- Shielding Integrity: During the design process, the shielding parts must be designed to seamlessly integrate with other parts of the equipment (such as the casing or seams) to ensure the entire device meets radiation protection standards.

- Protection Coverage: The design should consider the direction, intensity, and working conditions of the radiation source, ensuring all potential radiation paths are effectively shielded.

- Mechanical Strength and Stability Tungsten alloy’s high density and hardness give it excellent radiation protection capabilities, but it also means the material is more brittle and vulnerable to impacts, vibrations, or shocks that could cause cracking. Therefore, the design must ensure that the tungsten alloy shielding parts maintain adequate mechanical strength and stability in medical equipment, avoiding breakage or deformation during use to ensure safety.

- Impact Resistance Design: The design should take into account the potential impact or friction the shielding parts might endure, selecting appropriate thickness and shapes to enhance their impact resistance.

- Secure Installation: The shielding parts must be firmly installed to ensure they do not loosen or detach over time, which could compromise the safety of the equipment.

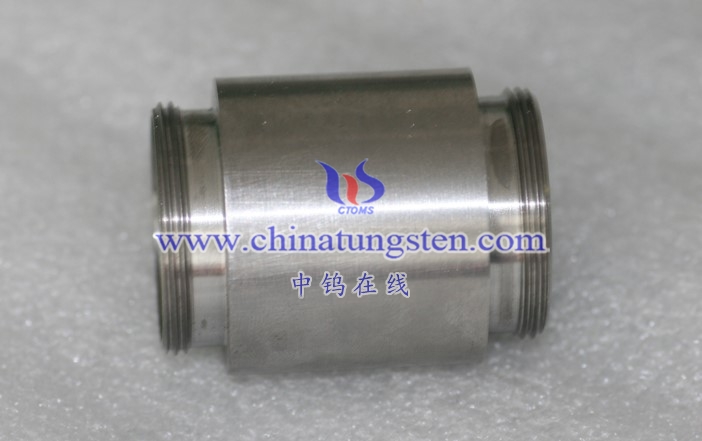

- Smooth Surface and Lack of Sharp Edges Tungsten alloy shielding parts often have complex geometries, so special attention must be given to their surface smoothness and edge treatments. Sharp edges or rough surfaces could injure operators during installation, maintenance, or use, especially with prolonged contact or accidental contact.

- No Sharp Edges Design: The design should avoid sharp angles or pointed edges, instead using smooth contours to reduce the risk of injury.

- Surface Treatment: To improve surface smoothness and reduce wear caused by rough surfaces, the tungsten alloy shielding parts may undergo polishing, sandblasting, or other surface treatments to enhance their safety during use.

- Weight and Structural Reasonableness Tungsten alloy’s high density typically results in heavier shielding parts, which increases the overall weight of the medical equipment. Overly heavy equipment may impact its transportation, installation, and maintenance, potentially increasing the labor intensity of operators and affecting safety.

- Weight Balance Design: In the design of tungsten alloy shielding parts, it’s important to not only ensure radiation protection effectiveness but also to optimize the dimensions and shape to reduce the total weight of the equipment. The design should ensure a reasonable center of gravity to prevent instability or operational difficulty.

- Convenient Installation and Maintenance: The design should also ensure that the shielding parts are easy to install and replace, minimizing risks during installation and maintenance.

- Environmental and Temperature Adaptability Tungsten alloy has a very high melting point and can withstand high temperatures. However, in certain medical equipment, such as radiation therapy machines and CT scanners, high temperatures can be generated inside the equipment. When tungsten alloy shielding parts work in high-temperature environments, the design should account for their thermal stability, ensuring they do not deform or degrade due to temperature fluctuations.

- Thermal Expansion Control: The design must consider the thermal expansion properties of tungsten alloy, ensuring the shielding parts maintain dimensional stability at high temperatures, without affecting the normal operation of the equipment.

- Heat Dissipation Design: Sometimes, heat dissipation holes or channels may need to be integrated into the tungsten alloy shielding parts to ensure the equipment doesn’t overheat during prolonged use, thereby protecting user safety.

- Environmental Friendliness and Non-Toxicity Compared to traditional shielding materials like lead, tungsten alloy is more environmentally friendly because it does not contain toxic substances and does not release harmful materials during use or disposal. Therefore, the design should ensure that tungsten alloy shielding parts meet environmental standards and do not cause pollution when the equipment is discarded.

- Eco-Friendly Material Selection: The design should prioritize the use of non-toxic, pollution-free materials and comply with relevant environmental regulations to ensure the equipment remains environmentally safe throughout its lifecycle.

- Recycling and Reuse: Tungsten alloy materials have high recyclability, so the design could consider the recycling and reuse of shielding parts to reduce resource waste and improve sustainability.

Conclusion: The design of tungsten alloy shielding parts must comprehensively consider user safety, ensuring that while they provide effective radiation protection, they do not pose potential health risks to operators or patients. The design should focus on radiation leakage protection, mechanical strength, surface safety, weight balance, thermal stability, and other factors to ensure the long-term safety and reliability of the shielding parts. Furthermore, the environmental friendliness and non-toxicity of tungsten alloy are crucial aspects that must also be considered in the design process.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595