Tungsten filaments can play a role in making electromagnetic pulse (EMP) protection equipment, but its specific application effect and applicability depend on the design of the equipment and the required performance indicators. Here are some relevant considerations:

- Electrical conductivity

Good electrical conductivity: Tungsten has good electrical conductivity and can be used to build circuits and connect parts. This can be beneficial in some EMP protection equipment, especially circuits that require fast response.

- High temperature and radiation resistance

High melting point: Tungsten has a very high melting point (about 3422°C), which makes it stable under extreme conditions (such as high temperature and radiation). This feature may have advantages for EMP protection equipment in some extreme environments.

- Shielding effect

Electromagnetic shielding: EMP protection equipment needs to effectively shield electromagnetic radiation. Tungsten itself is not the best shielding material, but it can be used as part of a composite material in some designs and combined with other materials with better shielding properties.

- Mechanical strength

High strength: Tungsten’s high strength makes it more stable under mechanical loads and suitable for use in high-pressure environments. This may be beneficial for certain applications that require physical protection.

- Application examples

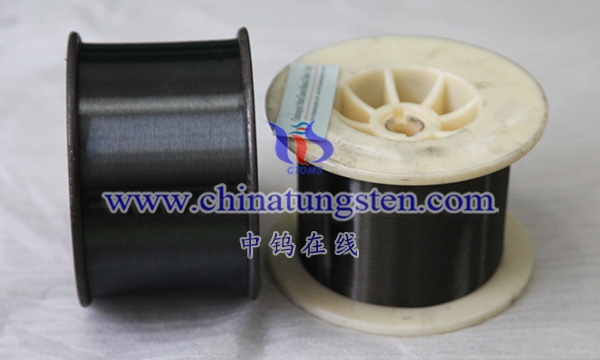

Cable sheath: Tungsten wire can be used to make cable sheaths to enhance the cable’s anti-interference ability to EMP.

Conductor: In some high-performance circuits, tungsten wire can be used as a conductor to help transmit signals and reduce EMP interference to signals.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595