Tungsten wire can play a certain role in protective equipment for the nuclear industry, mainly based on its following characteristics:

- High melting point

High temperature resistance: The melting point of tungsten is as high as about 3422°C, which enables it to remain stable in extremely high temperature environments and is suitable for use in high temperature places such as nuclear reactors.

- High density

Excellent radiation protection: Tungsten has a high density (about 19.3 g/cm³) and can effectively absorb and attenuate various types of radiation (such as gamma rays and X-rays), so it has potential application value in nuclear radiation protection.

- Mechanical strength

Good strength and toughness: The high strength of tungsten makes it perform well when subjected to mechanical loads, and it is suitable for parts of protective equipment that need to withstand impact and pressure.

- Corrosion resistance

Chemical stability: Tungsten exhibits good corrosion resistance in many chemical environments and is suitable for use in harsh chemical environments that may exist in the nuclear industry.

- Application scenarios

Radiation shielding: Tungsten wire can be used as a radiation shielding material to enhance the safety of nuclear facilities.

Protective equipment: In some personal protective equipment, tungsten wire can be used as a reinforcement material to improve the level of protection.

- Considerations

Cost: Tungsten is a relatively expensive material, which may limit its widespread use in certain applications.

Processability: The hardness and brittleness of tungsten may pose challenges during processing and molding.

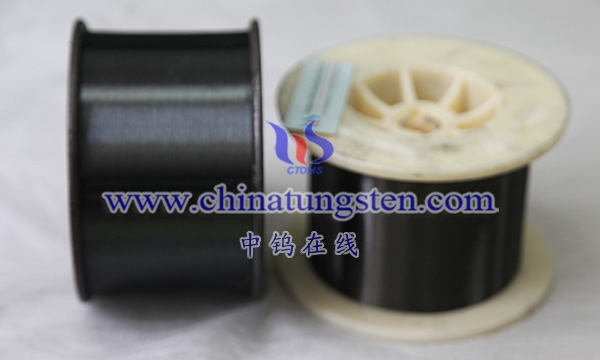

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595