The application of tungsten wire in corrosion-resistant liquid pipelines is not particularly common, mainly because of the following points:

- Corrosion resistance

Chemical stability: Tungsten itself has good corrosion resistance in certain strong acid and alkali environments. However, tungsten is not as corrosion resistant as some other materials (such as stainless steel or titanium), so it may not be the best choice in extremely corrosive environments.

Oxide layer: Under certain conditions, tungsten may form an oxide layer, which reduces its durability in certain corrosive liquids.

- Mechanical properties

High strength: Tungsten has extremely high strength and hardness and can withstand high pressure and temperature, which makes it advantageous in certain specific applications.

Brittleness: The brittleness of tungsten may cause the material to break in certain applications, especially under impact loads, so this needs to be considered during design.

- Application examples

Specific applications: In some specific high temperature, high pressure and corrosive media environments, tungsten can be used as a lining material or used to manufacture components (such as valves, joints, etc.) to improve corrosion resistance.

Alloys: Tungsten is often alloyed with other materials (such as nickel, chromium, etc.) to improve its overall corrosion resistance and toughness. Such alloys may be more suitable for use in corrosion-resistant liquid pipelines.

- Alternative materials

Stainless steel: Stainless steel is generally widely used in liquid pipelines due to its excellent corrosion resistance and good mechanical properties.

Titanium alloy: Titanium and its alloys excel in corrosion resistance, especially in the marine and chemical industries, and are suitable for use in corrosion-resistant environments.

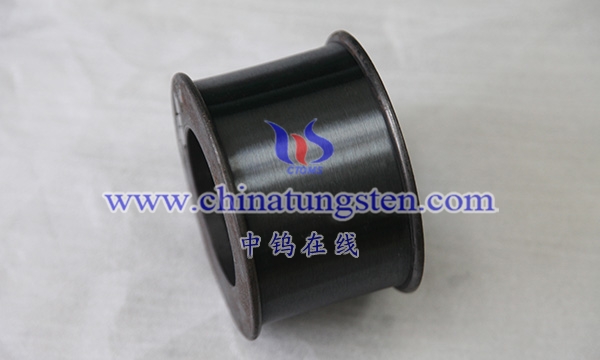

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595