The application of tungsten wire in ultra-high voltage equipment is mainly reflected in its excellent physical and chemical properties. The following is a detailed analysis of the application of tungsten wire in ultra-high voltage equipment:

- High melting point and stability

High melting point: The melting point of tungsten wire is as high as 3410°C (or 3422°C), which is the highest among all metals. This enables tungsten wire to withstand extremely high temperatures in ultra-high voltage equipment and ensure the stable operation of the equipment.

Stability: Tungsten wire is not easy to deform at high temperatures and has excellent thermal and chemical stability. This enables it to maintain its shape and performance for a long time in ultra-high voltage equipment, improving the reliability and service life of the equipment.

- Good electrical conductivity and thermal conductivity

Electrical conductivity: Tungsten wire has a high electrical conductivity, which can ensure the current transmission efficiency in ultra-high voltage equipment.

Thermal conductivity: Tungsten wire has good thermal conductivity, which can quickly export the heat generated in the equipment, avoid overheating of the equipment, and improve the heat dissipation performance of the equipment.

- High hardness and creep resistance

High hardness: The hardness of tungsten wire is very high, which can resist the mechanical stress and wear in ultra-high voltage equipment.

Creep resistance: Tungsten wire can maintain its shape and performance for a long time under high temperature and high pressure conditions, and is not prone to creep, which makes it have excellent stability and durability in ultra-high voltage equipment.

- Specific application areas

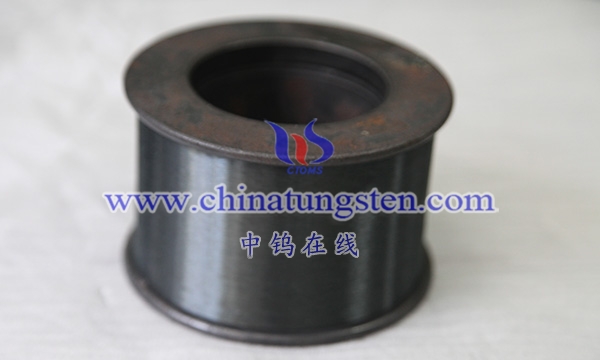

Electrode material: In ultra-high voltage equipment, tungsten wire is often used as an electrode material. Due to its high melting point and high conductivity, tungsten wire can work stably at high temperature and high current density to ensure the normal operation of the equipment.

Heating element: Tungsten wire is also used as a heating element in ultra-high voltage equipment. Its high melting point and good thermal conductivity enable it to work for a long time at high temperature and provide a stable heat source.

Vacuum tubes and electron tubes: In ultra-high voltage electronic equipment, tungsten wire can also be used as cathode and gate materials to improve the electron emission performance and stability of the equipment.

- Precautions

Although tungsten wire has a wide range of application prospects in extremely high voltage equipment, its production and use still face some challenges. For example, due to the extremely high melting point of tungsten wire, the energy consumption in its production process is relatively large. In addition, under high current, tungsten wire is prone to vibration, so it is necessary to pay attention to the control of current during use to avoid wire breakage.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595