Tungsten alloys are ideal for portable gamma radiation devices due to their exceptional combination of high density, superior radiation shielding, mechanical durability, and design flexibility—all tailored to the demands of mobility in applications like industrial radiography, medical fieldwork, and nuclear inspections. These properties ensure effective gamma containment, worker safety, and practical usability in compact, lightweight packages. Here’s what makes them stand out.

1. High Density for Compact Shielding

Why It Matters:

- Density: 17-19 g/cm³—over 50% denser than lead (11.34 g/cm³) and twice that of steel (~8 g/cm³)—means more gamma-stopping power per unit volume.

- Attenuation: For Ir-192 (0.2-1.4 MeV), tungsten’s half-value layer (HVL) is 6-7 mm; for Co-60 (1.17-1.33 MeV), it’s 9-10 mm. A 25 mm thick tungsten shield reduces intensity by over 90% (3-4 HVLs), compared to 33 mm of lead or 60 mm of steel.

Portable Benefit:

- A 10x10x10 cm tungsten holder (~10 kg) shields a 100 Ci source, dropping dose rates to <0.02 mSv/h at 1 meter—safe for carrying—while a lead equivalent weighs 15 kg and bulks up to 13x13x13 cm. This compactness is critical for handheld or backpacked devices in tight spaces like pipelines or hospital wards.

2. Superior Gamma Radiation Absorption

Why It Matters:

- Atomic Number (Z=74): High Z enhances photoelectric absorption (Z5 Z^5 ), Compton scattering, and pair production (Z2 Z^2 ), efficiently stopping gamma rays across a wide energy range (0.5-3 MeV, common in portable sources).

- Efficiency: A 20 mm tungsten shell outperforms 30 mm of lead for Cs-137 (0.662 MeV), reducing scatter and secondary radiation that could expose users.

Portable Benefit:

- Technicians using a 12 kg tungsten projector for Ir-192 in oil field NDT stay below 0.1 mSv per scan, with shielding tight enough for close-quarters work—ideal for a device slung over a shoulder or mounted on a cart.

3. Mechanical Durability for Field Use

Why It Matters:

- Strength: Tensile strength of 800-1000 MPa (e.g., 95W-Ni-Fe alloy) resists cracking from drops, vibrations, or rough handling—unlike brittle lead or less robust steel.

- Corrosion Resistance: Withstands moisture, salt, or dust—key for outdoor sites like offshore rigs or desert wells.

- Thermal Stability: Melting point >3400°C handles source heat (e.g., 50-100°C from a 100 Ci Co-60) without warping.

Portable Benefit:

- A 15 kg tungsten holder survives a 2-meter fall onto concrete during a pipeline inspection, keeping an Ir-192 source secure. Its durability ensures safety on the move, from muddy fields to icy platforms, without needing frequent replacements.

4. Machinability for Smart Design

Why It Matters:

- Alloying (e.g., nickel, iron) makes tungsten machinable—unlike pure tungsten’s brittleness—allowing precision features like collimators, shutters, or threads.

- Custom Features: A 5 mm collimator focuses gamma rays, a sliding plug controls exposure, and ergonomic handles ease carrying—all within a 10-15 kg package.

Portable Benefit:

- A radiography “pig” with a 25 mm tungsten shell and 5 mm collimator weighs 12 kg, with a remote crank (10 m cable) for hands-off operation. Workers scan welds with pinpoint accuracy, shielded to <0.01 mSv/h outside the beam, in a device that fits a pickup truck bed.

5. Non-Toxic and Safe Handling

Why It Matters:

- No Toxicity: Unlike lead, tungsten alloys pose no chemical risk if handled, dropped, or disposed of—crucial for fieldwork near ecosystems or populated areas.

- Regulatory Ease: Avoids lead’s hazmat protocols, simplifying transport and storage logistics.

Portable Benefit:

- A medical team using a 10 kg tungsten holder for Co-60 in a rural clinic doesn’t need gloves or special waste bins—shielding stays intact, and the environment stays clean, even if the device is misplaced temporarily.

6. Lightweight Enough for Portability

Why It Matters:

- While dense, tungsten’s shielding efficiency keeps total weight manageable. A 90% reduction in gamma intensity needs just 25-30 mm of tungsten (10-15 kg), versus 40 mm lead (15-20 kg) or 70 mm steel (20-25 kg).

- Design Tweaks: Hybrid builds (e.g., 20 mm tungsten core, 5 mm aluminum shell) trim weight to 8-12 kg, with handles or slings for mobility.

Portable Benefit:

- A 12 kg tungsten cask for Ir-192 fits a helicopter lift to an offshore rig, shielding to <0.02 mSv/h externally—light enough for one worker to carry with a strap, unlike a 25 kg steel alternative that needs two.

Real-World Examples

- Industrial: A 15 kg tungsten projector with a 30 mm shell and 5 mm collimator houses a 50 Ci Ir-192 source for pipeline NDT. Workers lug it through a swamp, scan a weld in 5 minutes (<0.05 mSv exposure), and spot a 2 mm crack—safe and mobile.

- Medical: A 10 kg tungsten holder for a 100 Ci Co-60 source in a portable teletherapy unit treats tumors in remote areas. Its 25 mm shield keeps doses <0.01 mSv/h at 1 meter, fitting a van for village-to-village travel.

- Nuclear: A 12 kg tungsten cask shields a Cs-137 source during decommissioning fieldwork, with a 20 mm wall ensuring <0.02 mSv/h—carried by hand to tight reactor zones.

Challenges and Solutions

- Cost: Tungsten’s $30-$50/kg (vs. $1-$5/kg steel) raises initial costs, but durability and safety justify it—cheaper than a radiation incident.

- Weight: At 10-15 kg, it’s heavier per volume than steel, but compact designs and carts offset this for portability.

- Supply: China’s 80% dominance risks shortages—stockpiling or recycling (30-50% recoverable) keeps devices flowing.

Customized R&D and Production of Tungsten, Molybdenum Products

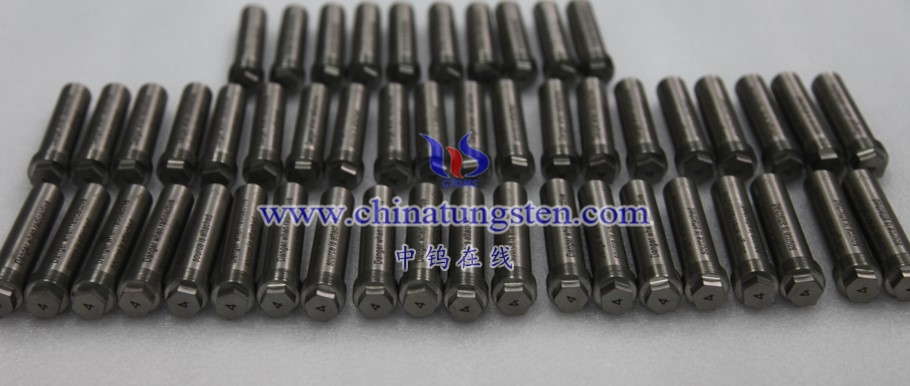

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595