Tungsten alloy source holders play a vital role in geologging and mining applications, particularly for housing radioactive sources used in density logging, porosity measurements, and mineral exploration. These holders must withstand harsh environmental conditions—such as high pressure, extreme temperatures, and corrosive fluids—while providing effective radiation shielding and structural durability. Here’s why tungsten alloys are an ideal solution and how they enhance performance in these industries.

Why Tungsten Alloys in Geologging and Mining?

- Superior Radiation Shielding: Tungsten alloys, with densities ranging from 17-18.5 g/cm³ (e.g., 95W-Ni-Fe), offer exceptional gamma-ray attenuation, critical for shielding sources like Cesium-137 (Cs-137) or Cobalt-60 (Co-60) used in wireline logging tools. Their high density allows for compact designs, reducing tool size in narrow boreholes.

- Mechanical Resilience: Geologging tools operate under pressures exceeding 20,000 psi (138 MPa) and temperatures up to 175°C in deep wells. Tungsten alloys, especially W-Ni-Fe, provide high tensile strength (up to 1000 MPa) and toughness, resisting deformation or cracking.

- Corrosion Resistance: In mining and geologging, exposure to saline water, hydrogen sulfide (H₂S), or acidic muds is common. W-Ni-Cu alloys, with enhanced corrosion resistance, maintain integrity in these aggressive environments compared to steel or lead.

- Compact and Lightweight Design: Compared to lead, tungsten’s higher density reduces the volume of shielding material needed, enabling slimmer tools that fit tight drilling constraints while minimizing weight penalties.

Applications in Geologging and Mining

- Density Logging: Tungsten alloy holders encase gamma sources (e.g., Cs-137, 0.662 MeV) in density sondes, ensuring safe containment and precise collimation for formation density measurements. The alloy’s density ensures a thin shield (e.g., 2-3 cm) achieves >90% attenuation.

- Porosity and Lithology Analysis: In neutron-gamma tools, tungsten holders shield gamma detectors from source emissions, improving signal accuracy for porosity and rock type identification.

- Mineral Exploration: Portable gamma-ray spectrometers use tungsten holders to protect operators and focus radiation, aiding in uranium, thorium, or potassium detection during surface surveys.

Advantages Over Alternatives

- Vs. Lead: Tungsten alloys provide 60% higher density, reducing holder thickness by ~40% (e.g., 2 cm vs. 3.5 cm for equivalent shielding), and eliminate toxicity risks.

- Vs. Steel: Steel’s lower density (7.8 g/cm³) requires triple the thickness, making tools bulky and less practical for deep wells.

- Vs. Depleted Uranium: While uranium matches tungsten’s density, its radioactivity and regulatory hurdles make tungsten a safer, simpler choice.

Practical Considerations

- Alloy Selection: 95W-Ni-Fe (18 g/cm³) is the go-to for most geologging tools due to its balance of shielding, strength, and machinability. W-Ni-Cu is preferred in corrosive or non-magnetic environments (e.g., near magnetometers).

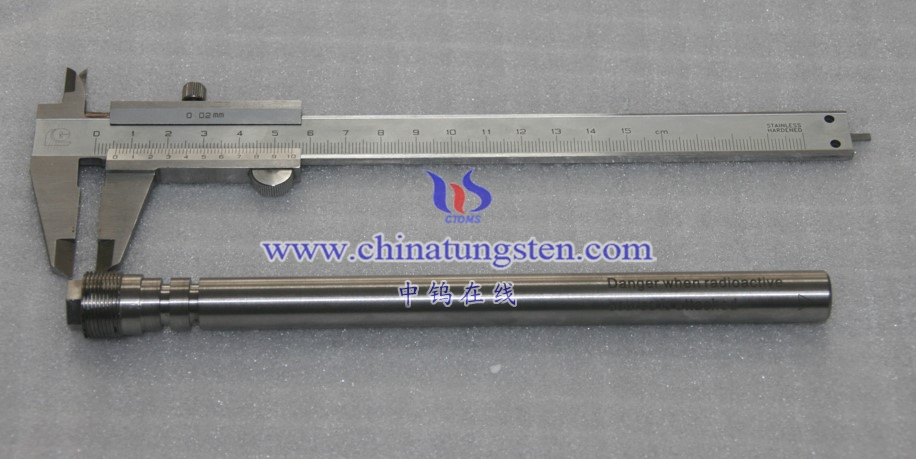

- Design: Holders often feature threaded or welded joints for source insertion, with precision machining to ensure tight tolerances (e.g., ±0.01 mm) for collimation.

- Cost: While more expensive than lead, tungsten’s longevity and performance justify the investment in high-stakes applications.

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten alloy products, please visit the website: http://www.tungsten-alloy.com/

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com|

Tel: +86 592 5129696 / 86 592 5129595