The tensile strength of tungsten wire can be tested by a special tensile test. The following is a detailed description of the test method for the tensile strength of tungsten wire:

- Test standards and equipment

Test standards: The test of the tensile strength of tungsten wire usually follows national or international standards, such as GB/T 228.1-2010 “Metallic materials tensile test Part 1: Room temperature test method” or GB/T 10573-2020 “Non-ferrous metal wire tensile method”. These standards specify the specific steps, specimen requirements, test conditions, etc. of the tensile test.

Test equipment: Commonly used test equipment includes electronic universal testing machines (such as EZ-LX) or tungsten wire tensile testers. These devices are able to apply a constant tensile speed and record the force and deformation data during the tensile process.

- Sample preparation

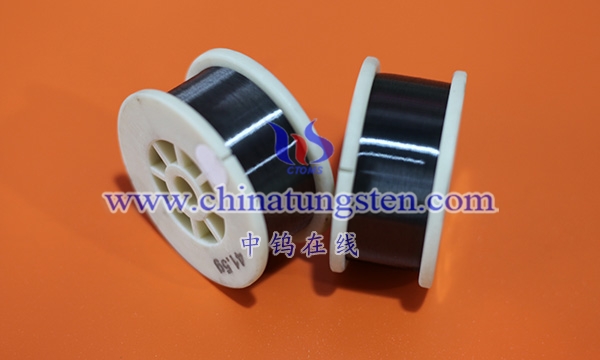

Specimen size: According to the test standard, the specimen should have a specific length and diameter. For extremely fine tungsten wires, such as tungsten wires with a diameter of 0.08mm or 0.0025mm, special attention should be paid to the clamping and protection of the specimen to avoid specimen breakage due to improper clamping during the test.

Specimen clamping: For thin tungsten wires that are easy to break, it is recommended to use pneumatic clamps or winding clamps for clamping. These clamps can provide better clamping force and protection to ensure that the specimen will not break due to improper clamping during the stretching process.

- Test steps

Install the specimen: Install the prepared specimen in the clamp of the tensile testing machine to ensure that the specimen is properly clamped and in a stretched state.

Set parameters: Set the tensile testing machine’s stretching speed, sampling frequency and other parameters according to the test standard. For thin tungsten wires, the stretching speed is usually slower, such as 1mm/min or 6mm/min, to ensure that the specimen has enough time to respond and deform during the stretching process.

Start the test: Start the tensile testing machine and start stretching the specimen. During the stretching process, the test machine will record the tensile force and deformation data of the specimen.

Record data: When the sample breaks, the tester will stop and record the maximum tensile force and the elongation of the sample. These data are used to calculate performance indicators such as tensile strength and elongation.

- Data processing and analysis

Calculate tensile strength: Tensile strength is the value obtained by dividing the maximum tensile force that the sample can withstand before breaking by the original cross-sectional area of the sample. It represents the ability of the sample to resist tensile damage.

Analyze elongation: Elongation is the increase in the sample relative to the original length during the stretching process. It reflects the plasticity and toughness of the sample.

Draw stress-strain curve: According to the recorded tensile force and deformation data, a stress-strain curve can be drawn. This curve can intuitively show the mechanical behavior of the sample during the stretching process, including the elastic stage, yield stage, and fracture stage.

- Precautions

Sample protection: For extremely fine tungsten wires, special attention should be paid to the protection of the sample to avoid sample breakage or performance degradation due to improper clamping, friction or contamination during the test.

Equipment calibration: Before the test, the tensile testing machine needs to be calibrated to ensure the accuracy and reliability of the test results.

Environmental control: The test environment (such as temperature, humidity, etc.) may affect the test results. Therefore, when conducting the test, it is necessary to control the test environment to eliminate its influence on the test results.

More details of tungsten wires, please visit website: http://tungsten.com.cn/tungsten-wires.html

Please contact CHINATUNGSTEN for inquiry and order of tungsten needles:

Email: sales@chinatungsten.com

Tel.: +86 592 5129595