CONTENT

Preface

1.1 Introduction

Definition and Importance of Tungsten Particles in Carbon and Sulfur Analysis

Academic Objectives and Target Audience of This Book

1.2 Historical evolution of tungsten particles in analytical chemistry

from traditional flux to modern carbon and sulfur analysis materials

1.3 How to Use This Book

Table of Contents and Index Guide

Chapter 1: Basic concepts of tungsten particles and their correlation with carbon and sulfur analysis

1.1 What is tungsten pellet?

1.2 Classification and analysis applicability of tungsten particles

1.3 Physical and chemical properties and analytical performance of tungsten particles

References

Chapter 2: Preparation Technology of Tungsten Particles for Carbon and Sulfur Analysis

2.1 Modern mainstream process: plasma spheroidization

2.2 Traditional preparation methods and analysis requirements

2.3 Other modern preparation technologies

2.4 Quality control and green preparation during the preparation process

References

Appendix: Equipment, instruments and raw and auxiliary materials involved in the tungsten granule production process

Chapter 3: Application performance and optimization of tungsten particles in carbon and sulfur analysis

3.1 Flux mechanism of tungsten particles in carbon and sulfur analysis

3.2 Comparison of application performance of tungsten particles prepared by different processes

3.3 Optimization of key parameters in the use of tungsten particles

3.4 Frontier technologies and prospects for improving tungsten particle performance

References

Chapter 4: Industrial Application and Case Analysis of Tungsten Particles in Carbon and Sulfur Analysis

4.1 Application of tungsten particles in the steel industry

4.2 Application of tungsten particles in geological and mineral analysis

4.3 Application of tungsten particles in energy material analysis

4.4 Typical case analysis and problem solving

References

Chapter 5: Future Development and Challenges of Tungsten Particles in Carbon and Sulfur Analysis

5.1 Future Trends of Tungsten Particle Preparation Technology

5.2 Direction of improving the application performance of tungsten particles

5.3 Challenges and coping strategies of tungsten particles in carbon and sulfur analysis

5.4 Greening and sustainable development of tungsten pellets

References

Chapter 6: Comprehensive evaluation and optimization suggestions of tungsten particles in carbon and sulfur analysis

6.1 Comprehensive evaluation of tungsten particle performance

6.2 Analysis of the adaptability of tungsten particles in different application scenarios

6.3 Technical Path and Implementation Strategy of Tungsten Granule Optimization

6.4 Prospects and promotion suggestions for tungsten pellet applications

References

Chapter 7: Technical integration and industrialization prospects of tungsten particles in carbon and sulfur analysis

7.1 Integration technology of tungsten particles and analytical equipment

7.2 Application of tungsten particles in automated detection systems

7.3 Key technologies and economic analysis of tungsten granule industrialization

7.4 Global Vision and Future Prospects of Tungsten Granule Technology Promotion

References

Chapter 8: The important role of tungsten particles as counterweight fillers

8.1 Core characteristics and applicability of tungsten particles as counterweight fillers

8.2 Unique technical advantages of tungsten particle weight filling

8.3 Industry Scenarios and Actual Cases of Tungsten Granules in Counterweight Application

8.4 Future potential and development direction of tungsten particle weight filling

References

Chapter 9: Terminology, Standards and Resources

9.1 Glossary of Tungsten Granule Related Terms

9.2 References and standards on tungsten particles

Academic Literature

Technical Standards

9.3 Recommended Resources

Appendix

Appendix A: Tungsten particle microstructure and analysis results

A.1 Microstructural characteristics of tungsten particles

A.2 Effect of microstructure on analysis results

A.3 Experimental data and microscopic analysis results

A.4 Comparison of experimental data and microscopic analysis results

Relationship between SEM/TEM images of tungsten particles and combustion efficiency

- Microstructural features revealed by SEM/TEM images

- The relationship between microstructure and combustion efficiency

- Experimental verification and image analysis results

Appendix B: Tungsten particle size and instrument parameter standards

B.1 Classification and characteristics of tungsten particle size

B.2 Matching criteria between instrument parameters and particle size

B.3 Experimental data and recommended parameter table

Standard Test Methods for Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys

Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques

GB/T 223.5-2008: Determination of carbon and sulfur content of steel and alloys

ISO 15350:2018: Iron and steel – Determination of total carbon and sulfur content by infrared absorption method after combustion in an induction furnace

Steel and Iron – Determination of Total Carbon and Sulfur Content – Infrared Absorption Method after Combustion in an Induction Furnace

Preface

1.1 Introduction

Definition and Importance of Tungsten Particles in Carbon and Sulfur Analysis

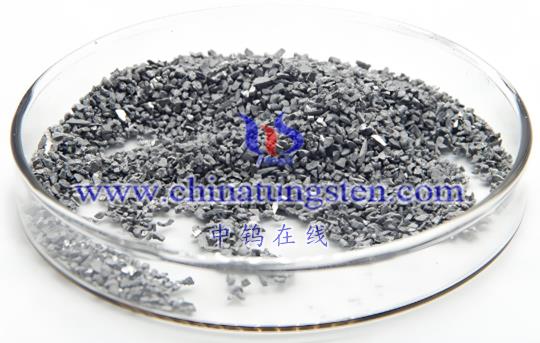

Tungsten particles, as a granular material with metallic tungsten (W) as the main component and processed by a specific process, play an indispensable role in the field of carbon and sulfur analysis due to its high melting point (3422°C), high density (19.25 g/ cm³ ) and excellent chemical stability . Carbon and sulfur analysis is a classic analysis method that converts carbon and sulfur in the sample into gas (such as CO₂ and SO₂ ) through high-temperature combustion and combines infrared detection technology to determine its content. It is widely used in steel, alloys, ores and organic materials. In this process, tungsten particles are usually used as flux, which can significantly improve the combustion efficiency of the sample and ensure the complete release of carbon and sulfur elements , thereby improving the accuracy and repeatability of the analysis.

Compared with other fluxes (such as tin particles and copper particles), tungsten particles can maintain structural integrity in a high-temperature oxygen environment due to their excellent thermal stability and oxidation resistance, avoid the introduction of interfering elements, and ensure the reliability of the test results. Its particle size (usually in the range of 0.1-5 mm) and morphology (spherical or irregular) have a direct impact on the fluxing effect, making it a key material for the design and operation optimization of carbon-sulfur analysis instruments. The purpose of this book is to systematically explain the preparation technology, mechanism of action, application scenarios and future development of tungsten particles in carbon-sulfur analysis , and to provide a comprehensive reference for researchers and industrial practitioners in the field of analytical chemistry.

Academic Objectives and Target Audience of This Book

The goal of this book is to fill the gap in the existing literature on the systematic research of this specific application field by deeply exploring the multi-dimensional characteristics of tungsten pellets in carbon and sulfur analysis . Academically, this book strives to reveal the intrinsic connection between the physical and chemical properties of tungsten pellets and their fluxing properties from the cross-perspective of materials science and analytical chemistry, analyze its applicability in different instruments and sample types, and explore the prospects for technological innovation. In terms of practicality, this book aims to provide technical guidance for laboratory operators, instrument development engineers, and quality control experts, including the preparation process of tungsten pellets, quality control standards, safety management specifications, and actual case analysis.

The target readers include but are not limited to the following groups: researchers in the field of analytical chemistry who focus on theoretical research on tungsten particles in carbon and sulfur analysis ; material scientists who explore new technologies for tungsten particle preparation and performance optimization; industrial practitioners, such as quality management personnel in steel mills, ore processing companies and testing institutions, who seek efficient and accurate analytical solutions; and college students and trainers who learn the basic principles and practical skills of carbon and sulfur analysis . This book strives to balance academic depth and breadth of application, and become an authoritative guide in the field of carbon and sulfur analysis .

1.2 Historical evolution of tungsten particles in analytical chemistry

from traditional flux to modern carbon and sulfur analysis materials

Tungsten particles as carbon and sulfur analysis materials is the product of the joint development of analytical chemistry and materials science. The origin of carbon and sulfur analysis can be traced back to the chemical titration method in the late 19th century. At that time, the carbon and sulfur content in the sample was mainly determined by wet method , which was inefficient and limited by complex matrices. In the early 20th century, with the introduction of the combustion method, the concept of flux gradually took shape. In the early days, iron powder or copper powder was mostly used to promote the oxidation reaction of samples at high temperatures. However, these traditional fluxes often fail due to their low melting point or easy oxidation when faced with high-melting-point or low-reactivity samples (such as high-alloy steel and ceramics), resulting in incomplete release of carbon and sulfur and limited analysis accuracy.

The introduction of tungsten particles began in the mid-20th century, along with the rise of infrared detection technology. As a high-melting-point, corrosion-resistant metal, tungsten particles were tested for carbon-sulfur analysis in the 1950s to replace easily fusible tin particles and chemically active copper particles. Early tungsten particles were mostly prepared by simple crushing, with uneven particle size distribution, but their stability and fluxing effect in high-temperature combustion furnaces have shown potential. In the 1970s , with the popularization of high-frequency induction furnaces and resistance furnaces, the application of tungsten particles has gradually been standardized. Its high density and thermal conductivity have been proven to effectively improve the uniformity of sample combustion and significantly reduce analytical errors.

In the 21st century, the preparation technology of tungsten particles has been further improved. Plasma spheroidization and vapor deposition methods have made the industrial production of spherical, high-purity tungsten particles possible. These technological advances not only optimize the particle size consistency and surface characteristics of tungsten particles, but also promote their application in trace carbon and sulfur analysis . For example, in the analysis of geological samples and organic materials, tungsten particles can support lower detection limits (ppm level), meeting the needs of modern industry for high-precision analysis. The evolution from traditional flux to modern carbon and sulfur analysis materials reflects the core position of tungsten particles in technological innovation and also lays an important foundation for its use in the field of analytical chemistry.

1.3 How to Use This Book

Table of Contents and Index Guide

This book has a clear directory structure to facilitate readers to quickly locate the required information. The book is divided into seven chapters and an appendix. Starting from the basic concept of tungsten particles, it gradually goes into its preparation technology, mechanism of action, instrument application, safety management and development trend in carbon and sulfur analysis . Chapter 1 introduces the definition, classification and physical and chemical properties of tungsten particles, laying a theoretical foundation; Chapter 2 focuses on the preparation process and quality control, highlighting technical details; Chapter 3 analyzes the mechanism of action of tungsten particles as a flux and its comparison with other materials; Chapter 4 discusses its specific application in carbon and sulfur analysis instruments, supplemented by case analysis; Chapter 5 provides safety and management specifications; Chapter 6 looks forward to development trends and market dynamics; Chapter 7 organizes terminology, standards and resources to provide support for international research. The appendix contains microstructure pictures, standard comparisons and case presentations to enhance visual and data support.

To improve ease of use, this book provides a multilingual glossary in Chapter 7 (including Chinese, English, Japanese, Korean, German, and Russian), and an alphabetical term index is compiled in Appendix D, covering the core vocabulary related to carbon-sulfur analysis and tungsten particles . Readers can navigate to specific chapters through the catalog according to their research needs, or use the term index to find the definition and source of professional terms. In addition, the book cites international standards (such as ASTM E1019-18) and academic literature (such as “Application of Tungsten Materials in Analytical Chemistry”), and recommends databases such as ScienceDirect for readers to further consult.

Readers are advised to choose a reading path based on their own background: beginners can start with Chapter 1 to gradually understand the basic knowledge of tungsten particles; technicians can directly refer to Chapters 2 and 4 to obtain preparation and application details; researchers can focus on Chapters 3 and 6 to explore mechanisms and future trends. This book aims to be a reference book with both academic depth and practical value, helping readers to fully master the core knowledge of tungsten particles in carbon and sulfur analysis .

READ MORE:What’s Tungsten Granule /Flux

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

For more information about tungsten chemical products please visit the website: tungsten-powder.com

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595