Molybdenum crucibles have poor applicability in oxidizing environments, mainly because molybdenum easily reacts with oxygen at high temperatures, resulting in rapid corrosion and material loss. The following is an analysis of the performance of molybdenum crucibles in oxidizing environments:

- Behavior of Molybdenum in Oxidizing Environment

Oxidation reaction:

Molybdenum reacts rapidly with oxygen in an oxygen-containing environment (such as air or an oxygen atmosphere) above about 500°C to form the volatile oxide MoO ₃ (molybdenum trioxide).

MoO₃ will sublime at high temperatures, causing the surface of the molybdenum crucible to be continuously worn away, corroded, thinned, and even cracked.

Temperature influence:

Below 400°C: Molybdenum oxidizes more slowly and short-term use may be possible, but an oxide layer will still form slowly.

Above 500-600°C: The oxidation rate accelerates significantly and the crucible surface deteriorates rapidly.

Above 800°C: MoO₃ evaporates violently and the molybdenum crucible will be severely damaged in a short time.

- Suitability Assessment

Not suitable for oxidizing environment:

Due to high temperature oxidation issues, molybdenum crucibles are not suitable for long-term use in air or other oxidizing atmospheres (such as environments containing oxygen, water vapor or carbon dioxide), especially in high temperature processes above 500°C.

In an oxidizing environment, the life of a molybdenum crucible is extremely short and can usually only support short-term or low-temperature operation.

Low temperature or short-term use:

If the process temperature is below 400°C and the exposure time is short, molybdenum crucibles may be used with some difficulty, but the degree of oxidation should still be monitored and other more oxidation resistant materials (such as platinum, alumina crucibles) should be considered.

- Limitations related to oxidative environments

Corrosiveness: The volatilization of MoO₃ caused by oxidation will make the crucible surface rough and thin, reduce its mechanical strength and sealing, and ultimately affect the process quality.

Contamination Risk: MoO₃ volatiles may deposit on process equipment or materials and contaminate samples, which is unacceptable especially in applications with high purity requirements (such as semiconductor manufacturing).

Thermal stress: The oxide layer formed during the oxidation process may induce thermal stress and cause the crucible to crack.

- Alternative environment and improvement measures

Priority Environment:

Molybdenum crucibles are more suitable for use in vacuum or inert atmospheres (such as argon, nitrogen) and reducing atmospheres (such as hydrogen). Under these conditions, molybdenum crucibles can withstand 1700-2000°C or higher without significant corrosion.

Improvement measures:

a molybdenum crucible in an oxidizing environment, you can try the following methods, but the effect is limited:

Surface coating: Applying an oxidation-resistant coating (such as alumina, zirconia, or silicide) can temporarily retard oxidation, but the coating may flake off or fail at high temperatures.

Low temperature operation: Control the process temperature below 400°C to reduce the oxidation rate.

Atmosphere Control: Whenever possible, minimize oxygen concentration (e.g., use local inert gas blanketing).

======================================================================

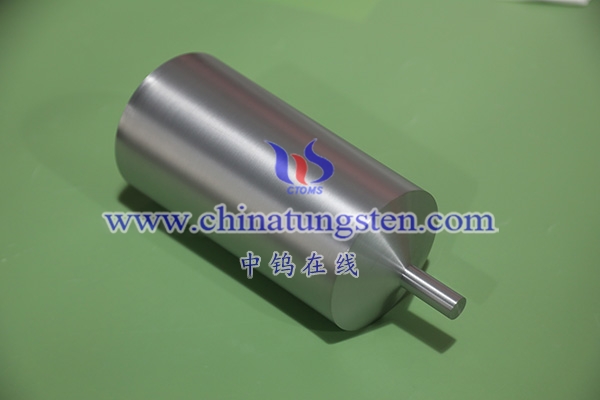

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595