Molybdenum crucible (or its reciprocal resistivity) depends on the purity, temperature and microstructure of molybdenum. As a metallic material, molybdenum has good conductivity and is suitable for high temperature applications that require conductive properties. The following is a detailed analysis of the conductivity of molybdenum crucible:

- Basic characteristics of conductivity

Room temperature conductivity:

high-purity molybdenum (99.95% or more) at room temperature (about 25°C) is about 18.7 × 10 ⁶ S/m (Siemens per meter), corresponding to a resistivity of 5.34 × 10 ⁻⁸ Ω· m (or 53.4 nΩ·m ).

This shows that molybdenum is a good conductor, but its conductivity is lower than that of copper (~58 × 10 ⁶ S/m) or silver (~63 × 10 ⁶ S/m).

- Effect of temperature on conductivity

As temperature increases, conductivity decreases:

As temperature increases, the resistivity of molybdenum increases (due to enhanced electron scattering), and the conductivity decreases accordingly. The following is a typical data of resistivity change with temperature:

25°C: Resistivity ~5.34 × 10 ⁻⁸ Ω· m, conductivity ~18.7 × 10 ⁶ S/m.

500°C: Resistivity ~20 × 10 ⁻⁸ Ω· m, conductivity ~5 × 10 ⁶ S/m.

1000°C: Resistivity ~35 × 10 ⁻⁸ Ω· m, conductivity ~2.86 × 10 ⁶ S/m.

1500°C: Resistivity ~50 × 10 ⁻⁸ Ω· m, conductivity ~2 × 10 ⁶ S/m.

2000° : Resistivity ~65 × 10 ⁻⁸ Ω· m, conductivity ~1.54 × 10 ⁶ S/m.

These values are based on high purity molybdenum; the conductivity of actual crucibles may vary slightly due to impurities or manufacturing processes.

- Factors affecting conductivity

purity:

High purity molybdenum has higher conductivity, and impurities (such as carbon, oxygen, and nitrogen) will increase resistivity and reduce conductivity.

Alloying:

The electrical conductivity of molybdenum alloys (such as Mo-W, Mo-La) is usually lower than that of pure molybdenum because the alloying elements introduce additional electron scattering.

Microstructure:

Forged, sintered or rolled molybdenum crucibles may have slightly varying conductivity due to grain size and defects.

temperature:

At high temperatures, lattice vibration and electron scattering are enhanced, resulting in a significant increase in resistivity and a decrease in conductivity.

- Practical application significance

High temperature conductivity:

Although the electrical conductivity of molybdenum decreases at high temperatures, it can still maintain ~1.5 × 10 ⁶ S/m at 2000°C, which is better than many high-temperature resistant materials (such as ceramic crucibles) and is suitable for processes that require conductive properties.

Typical applications:

Semiconductor manufacturing: In crystal growth or heat treatment, molybdenum crucibles can be used as conductive parts in conjunction with induction heating or electrode systems.

Vacuum furnace: Molybdenum crucible can be used for high temperature electric heating process in vacuum or inert atmosphere.

Arc Melting: Molybdenum ‘s electrical conductivity supports stable current conduction in arc or plasma processes.

Compared with other materials:

The electrical conductivity of molybdenum is higher than that of tungsten (~18.2 × 10 ⁶ S/m vs. ~10 × 10 ⁶ S/m at 25 ° C), but lower than that of copper or silver.

Compared to ceramics (such as alumina, which has a conductivity close to zero), molybdenum ‘s electrical conductivity is a significant advantage.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

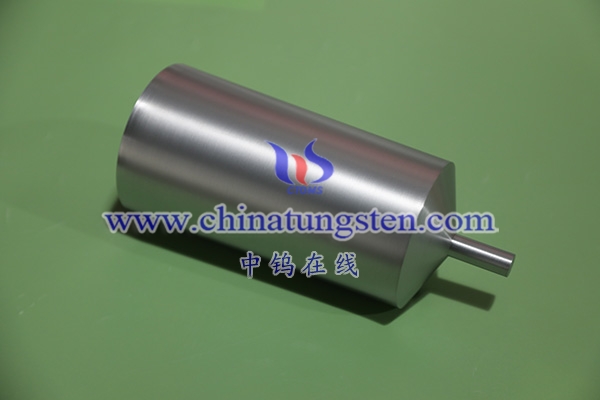

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595