Molybdenum crucibles are not easy to deform under normal use conditions, but their deformation risk depends on temperature, mechanical stress, manufacturing process and use environment. The following is a brief analysis:

- Anti-deformation performance of molybdenum crucible

High strength: Molybdenum has high strength and hardness (tensile strength of about 500-700 MPa at room temperature) and maintains a certain mechanical strength at high temperatures (up to ~2000°C), making it suitable for bearing the weight and thermal stress of the material in the crucible.

High melting point: Molybdenum has a melting point of 2623°C and can withstand temperatures of 1700-2000°C in a vacuum or inert atmosphere, which is much higher than most application temperatures, reducing the risk of softening and deformation.

- Factors that may cause deformation

High temperature creep: Above 1200°C, molybdenum may creep (slowly deform), especially under long-term high temperatures and continuous mechanical loads. The creep rate increases significantly with increasing temperature.

Thermal shock: Rapid temperature changes can induce thermal stresses that can cause cracking or slight deformation of the crucible, especially in crucibles with thin walls or uneven designs.

Recrystallization embrittlement: Molybdenum will recrystallize after long-term use above 1200°C, resulting in grain growth and increased brittleness, which may reduce the ability to resist deformation.

Manufacturing defects: Low-quality crucibles (such as internal microcracks, uneven grains) are more likely to deform or crack at high temperatures.

External stresses: Deformation may be caused by excessive material loading or improper mechanical support.

- Influence of use environment

Vacuum/inert atmosphere: In vacuum or inert gas (such as argon, hydrogen), molybdenum crucible has the best deformation resistance because there is no oxidation loss and the structure is stable.

Oxidizing environment: In an oxygen-containing atmosphere, molybdenum oxidizes rapidly above 500°C to generate volatile MoO₃, which causes surface corrosion and structural weakening, increasing the risk of deformation or cracking (but oxidizing environments are generally not recommended).

- Measures to prevent deformation

Optimized design: Choose a crucible with uniform wall thickness and reasonable structure to enhance its anti-deformation ability.

Control temperature: Avoid prolonged exposure to the extreme temperature of molybdenum (~2000°C), and try to shorten high temperature exposure time.

Slow heating/cooling: reduces thermal shock and lowers thermal stress.

High-quality materials: Use high-purity molybdenum (above 99.95%) or molybdenum alloys (such as Mo-La, Mo-W) to improve high-temperature strength and creep resistance.

Proper loading: Avoid overloading the material and ensure that the crucible is evenly stressed.

======================================================================

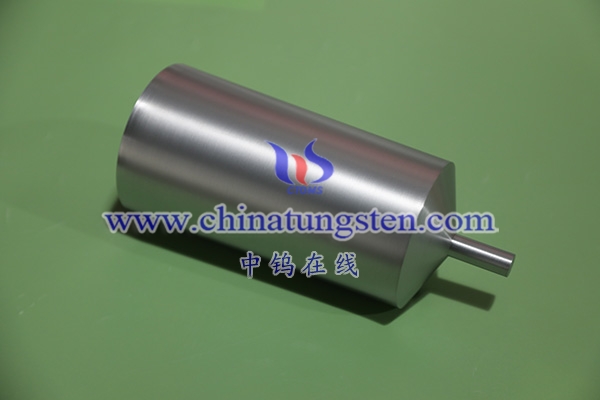

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595