Molybdenum crucibles depend on the use environment, temperature and contact materials. In general, molybdenum shows good chemical stability under certain conditions, but it will corrode in certain environments. The following is a brief analysis:

- Overview of Chemical Stability

advantage:

Molybdenum has excellent chemical stability in vacuum, inert atmospheres (such as argon, nitrogen) or reducing atmospheres (such as hydrogen), withstands high temperatures (to ~2000°C) and is stable to a variety of molten metals and compounds.

Limitations:

In an oxidizing environment or when in contact with certain highly corrosive substances, molybdenum is prone to chemical reactions, leading to corrosion or loss.

- Specific chemical stability

- Vacuum or inert atmosphere

Excellent stability:

In vacuum or inert gas, molybdenum crucibles hardly react with the environment and can withstand 1700-2000°C or higher, making them suitable for high-purity processes such as semiconductor crystal growth and rare metal smelting.

It will not oxidize or volatilize, the surface remains smooth and the service life is long.

- Reducing atmosphere (such as hydrogen)

Good stability:

Molybdenum is highly stable in pure hydrogen, which prevents oxidation and is suitable for high-temperature reduction processes (such as powder metallurgy).

Note: If hydrogen contains trace amounts of oxygen or water vapor, it may cause slight oxidation; long-term high temperature exposure may cause slight hydrogen embrittlement.

- Oxidizing environment (such as air)

Poor stability:

Molybdenum oxidizes rapidly in an oxygen-containing atmosphere (air, oxygen) above 500°C to form volatile MoO ₃, which causes surface corrosion and material loss.

Oxidation is slow below 400°C and short-term use is possible, but not recommended.

Improvement: Surface coatings (such as aluminum oxide, silicide) can temporarily delay oxidation, but the effect is limited.

- Acid, alkali, salt solution

Acidic environment:

It has good corrosion resistance to non-oxidizing acids (such as hydrochloric acid and dilute sulfuric acid), especially at low temperatures.

It has poor corrosion resistance to oxidizing acids (such as nitric acid and hot concentrated sulfuric acid) and is easily corroded.

Alkaline environment:

The corrosion resistance is average in dilute alkaline solutions (such as sodium hydroxide), and high temperature or strong alkali (such as molten NaOH) will cause corrosion.

Saline solution:

It has good corrosion resistance to neutral salt solutions (such as sodium chloride), but may be damaged in salt solutions containing oxidants.

- Molten metals and compounds

Tolerance:

It has good corrosion resistance to many molten metals (such as gold, silver, copper, aluminum, and rare metals) and is suitable for smelting precious metals or alloys.

It may react slightly with some active materials (such as molten titanium, zirconium, carbon, silicon) to form carbides or silicides, and compatibility needs to be evaluated.

limit:

Molten glass, oxides (such as SiO ₂) or fluorides may corrode molybdenum at high temperatures and must be avoided or a protective coating must be used.

- Factors affecting chemical stability

Temperature: High temperatures accelerate chemical reactions, especially in the presence of oxidizing or reactive species.

Purity: High-purity molybdenum (above 99.95%) has better chemical stability, and impurities may reduce corrosion resistance.

Surface Condition: Polished or coated surfaces can reduce reactivity and extend life.

Atmosphere: Vacuum/inert/reducing atmosphere significantly improves stability, while oxidizing atmosphere weakens stability.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

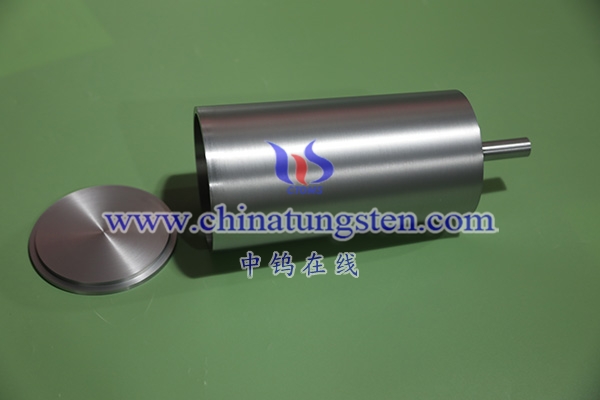

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595