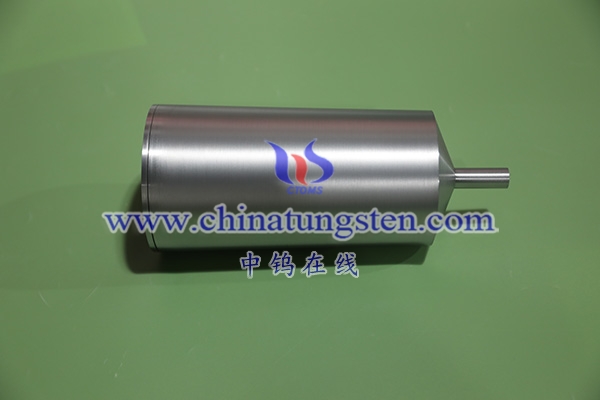

Sintered molybdenum crucible is a kind of molybdenum crucible manufactured by powder metallurgy sintering process, which is widely used in high temperature industry and scientific research. The following is a brief description of its definition, characteristics, manufacturing process and application:

- Definition

Sintered molybdenum crucible is made of high-purity molybdenum powder (purity is usually ≥99.95%) as raw material, through pressing and high-temperature sintering process. Its main feature is that the solid structure is formed by the combination of powder particles at high temperature, which is suitable for high-temperature processes in vacuum, inert or reducing atmosphere.

- Manufacturing Process

Sintered molybdenum crucible includes the following key steps:

Molybdenum powder preparation: Use high-purity molybdenum powder, sieve to ensure uniform particle size, and add a small amount of binder (such as polyvinyl alcohol) if necessary.

Pressing: Molybdenum powder is loaded into a mold and pressed into a crucible green body by a hydraulic press (100-300 MPa) or cold isostatic pressing (CIP).

Pre-sintering: Low temperature sintering at 800-1200°C in vacuum or hydrogen atmosphere to remove binder and moisture.

High temperature sintering: sintering in a vacuum or hydrogen furnace at 1800-2200°C for 2-6 hours to combine the molybdenum powder particles and the crucible density reaches 90-95% of the theoretical density (~10.2 g/cm³).

Finishing: Adjust the size and surface finish by turning, grinding or polishing, and apply an anti-oxidation coating if necessary.

Quality inspection: Check size, density, microstructure and defects (such as cracks, pores).

- Features

advantage:

Lower cost: Compared with forging or spinning, sintering process is suitable for mass production and has high material utilization rate.

Flexible shape: complex shapes and large crucibles can be manufactured, and the mold design is flexible.

High temperature performance: withstands 1700-2000°C in vacuum/inert atmosphere, good chemical stability.

Limitations:

Slightly lower density: usually 90-95% theoretical density, mechanical strength and durability are slightly lower than forged crucibles.

Rough surface: The surface may not be smooth enough after sintering and requires additional processing.

High temperature oxidation: It is easy to oxidize in an oxygen-containing environment (> 500°C) to generate volatile MoO ₃, and an oxidizing atmosphere should be avoided.

- Application

Sintered molybdenum crucibles are widely used in the following fields due to their cost-effectiveness and high temperature performance:

Metallurgical industry: smelting rare metals (such as tungsten and tantalum), precious metals (such as gold and silver) or alloys.

Glass/ceramic industry: high temperature melting of special glass or sintering of ceramics.

Laboratory research: for high temperature experiments, material heat treatment or sintering processes.

Others: Powder metallurgy, vacuum heat treatment and other scenarios that require high-temperature corrosion-resistant containers.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595