Metallurgical crucible is the key container used in high-temperature smelting, refining, alloying and other processes in the metallurgical industry. They are usually made of high-temperature resistant and corrosion-resistant materials and can withstand the high temperature and chemical erosion of molten metals.

- Main characteristics of metallurgical crucibles

High temperature resistance: Able to withstand high temperatures of molten metal (usually above 1000°C, some special materials can withstand above 3000°C).

Corrosion resistance: It has good corrosion resistance to molten metal and slag, and avoids the introduction of impurities.

Thermal stability: Maintain structural stability at high temperatures to avoid cracking or deformation due to thermal stress.

Thermal conductivity: Good thermal conductivity helps to evenly heat the molten metal and improve smelting efficiency.

- Commonly used materials

The material selection of metallurgical crucibles depends on the type of smelting metal, temperature and process requirements. Common materials include:

Graphite Crucible:

Features: high temperature resistance, good thermal conductivity, relatively low price.

Application: Commonly used in the smelting of non-ferrous metals such as copper and aluminum.

Corundum crucible (alumina crucible):

Features: high purity, high temperature resistance, chemical corrosion resistance.

Application: Suitable for smelting of high-temperature alloys and rare metals.

Quartz crucible:

Features: transparent, high temperature resistant, good chemical stability.

Application: Mainly used for melting semiconductor materials (such as silicon and germanium).

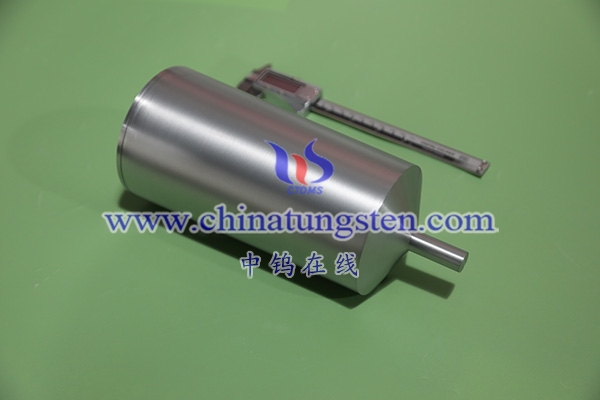

Molybdenum crucible, tungsten crucible:

Features: high melting point, high strength, corrosion resistance.

Application: Used for ultra-high temperature smelting, such as titanium, zirconium and other refractory metals.

Magnesium oxide crucible:

Features: high temperature resistance, corrosion resistance, good thermal stability.

Application: Suitable for melting of high temperature alloys and ceramic materials.

- Application fields

Non-ferrous metal smelting: smelting and casting of metals such as copper, aluminum, zinc, etc.

Preparation of rare metals and high-temperature alloys: such as smelting of metals such as titanium, zirconium, tungsten, molybdenum and their alloys.

Preparation of semiconductor materials: such as melting and purification of single crystal silicon and polycrystalline silicon.

Preparation of ceramic materials: melting and forming of ceramic materials such as alumina and zirconia.

Laboratory research: used for high temperature experiments in fields such as materials science and metallurgical engineering.

- Considerations for choosing a crucible

Type of smelting metal: Different metals have different melting points and chemical properties, so it is necessary to choose the appropriate crucible material.

Melting temperature: For high temperature melting, you need to choose a crucible with excellent high temperature resistance.

Process requirements: For vacuum melting, a crucible with good airtightness should be selected.

Cost: The prices of crucibles made of different materials vary greatly, so you need to choose according to your budget.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595