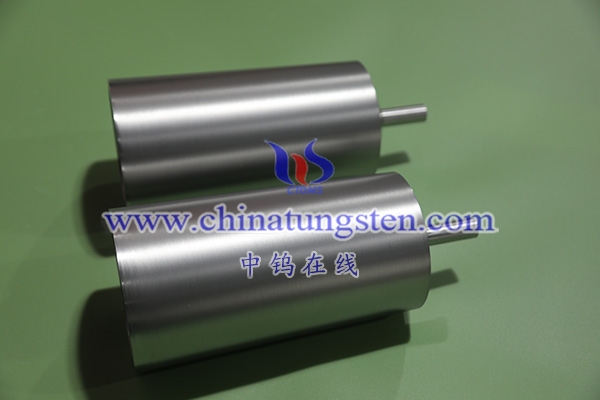

Cylindrical crucible is a high-temperature container with a standard cylindrical shape, which is widely used in materials science, chemical experiments, metallurgy and ceramic manufacturing.

- Definition and Characteristics

Geometric shapes

The cylindrical crucible consists of a circular bottom and vertical side walls, and the ratio of height to diameter can be adjusted according to needs.

Typical designs include flat bottom, round bottom or with ears (for easier clamping).

Material diversity

Refractory materials: alumina, silicon carbide, corundum, etc., suitable for high temperature melting.

Ceramic materials: Quartz, Boron Nitride, for use in chemically corrosive environments.

Metal materials: platinum, molybdenum, suitable for ultra-high temperature or high purity experiments.

Key Performance

High temperature resistance: Can withstand temperatures above 1000°C (some materials up to 2000°C).

Chemical stability: resist acid and alkali corrosion and avoid contamination by impurities.

Thermal conductivity: Graphite crucible has excellent thermal conductivity and is suitable for rapid heating.

- Application Fields

| field | Application Scenario |

| Materials Science | Preparation of molten metals and alloys (such as titanium alloys and high-temperature ceramics). |

| Chemical Experiments | Ashing analysis, sample melting (such as X-ray fluorescence spectroscopy analysis). |

| Metallurgical Industry | Precious metal refining (such as platinum and gold smelting). |

| Semiconductor Manufacturing | High purity quartz crucibles are used for single crystal silicon pulling. |

| Ceramic Manufacturing | Molten glass and glaze firing. |

- Technical parameters and selection

Key Parameters

Size: diameter 50mm-500mm, height 100mm-1000mm (customizable).

Wall thickness: 5mm-50mm (adjusted according to pressure resistance requirements).

Purity: High purity materials (such as 99.99% quartz) are used in the semiconductor field.

Selection basis

Experimental temperature: For high temperature experiments (>1600℃), choose graphite and zirconia; for medium temperature experiments (1000℃-1600℃), choose alumina.

Chemical environment: For strong acid, choose platinum or corundum; for alkaline environment, choose alumina.

Cost and life: Ceramic crucibles have low cost but short life, while platinum crucibles have high cost but are reusable.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595