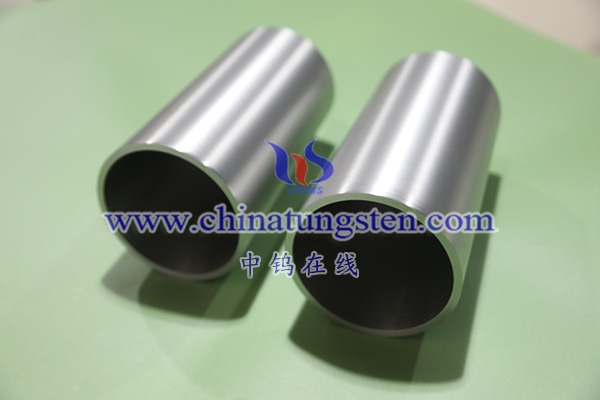

A conical crucible is an experimental container shaped like a cone, with a small base that gradually expands upwards to form a larger opening.

- Features

Design advantages:

Quick response to temperature changes: Heat can be quickly transferred from the bottom to the entire crucible body, with high heating efficiency.

Easy to operate: The larger opening makes it easier for the experimenter to perform sampling, observation and other operations.

Suitable for precise temperature control: Suitable for experiments that require precise temperature control, such as crystal growth, material synthesis, etc.

Structural features:

a larger temperature difference is formed with the crucible cover.

The unique shape ensures good contact between the crystal and the crucible wall during growth, which is beneficial to improving the growth efficiency of the crystal.

- Application fields

Crystal Growth:

In crystal growth experiments, the conical crucible can provide a stable temperature gradient, which is conducive to the uniform growth of crystals.

For example, in the aluminum nitride crystal growth experiment, the lower wall of the conical tungsten crucible is thicker, the induction heating efficiency is high, the temperature at the bottom of the crucible is higher, and a large temperature difference is formed with the crucible cover, which is conducive to the crystallization of aluminum nitride on the cover.

Material synthesis:

Used for high-temperature synthesis of new materials, such as ceramics, intermetallic compounds, etc.

The shape design of the conical crucible enables it to respond quickly to temperature changes during the heating process, which is beneficial to the uniform synthesis of materials.

Metal smelting:

Conical crucibles can be used to smelt non-ferrous metals such as copper and aluminum, or to prepare alloys.

Its larger opening design makes sampling and observation during the smelting process more convenient.

- Material selection

Conical crucibles can be made of different materials according to experimental requirements, such as:

Tungsten alloy: has high melting point, high strength and good corrosion resistance, suitable for high temperature, high pressure and highly corrosive environment.

Graphite: Good thermal conductivity and high temperature resistance, but not suitable for strong oxidizing environments.

Ceramic materials: such as alumina, quartz, etc., are resistant to high temperatures and have good chemical stability.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595