A rectangular crucible is a high-temperature experimental container with a rectangular or square cross-section, which is mainly used in experimental scenarios that require a specific shape or large capacity processing.

- Core Features

Geometric design

Cross-section: Rectangular or square, as opposed to the traditional cylindrical crucible.

Wall thickness: can be designed to be uniform or gradient thickness to meet different heat conduction requirements.

Opening design: Large opening facilitates sample loading and removal, suitable for batch processing.

Material advantages

Refractory ceramics: alumina, silicon carbide, etc., which are resistant to high temperatures and have strong chemical stability.

Metal materials: platinum, molybdenum, etc., suitable for ultra-high temperature or high-purity experiments.

Composite materials: Ceramic-based composite materials that combine heat resistance and mechanical strength.

- Application Scenarios

| field | Specific applications |

| Material synthesis | Molten metal alloys and ceramic precursors, the rectangular structure is conducive to uniform mixing and directional solidification. |

| Chemical analysis | Large sample melting (such as XRF analysis), the opening design facilitates sample operation. |

| Semiconductor Manufacturing | Specially shaped crucibles are used for wafer- level material growth, with a rectangular structure that matches the wafer size. |

| Metallurgical Industry | Batch smelting of precious metals (such as platinum and gold) to improve production efficiency. |

| Heat Treatment | The rectangular cavity design optimizes the heat conduction path, achieving rapid temperature rise and uniform heating. |

- Technical advantages

Space Utilization

The rectangular structure can make full use of the furnace space and is suitable for batch experiments or large-capacity sample processing.

Heat transfer optimization

The wall thickness gradient design can control the temperature gradient and achieve directional solidification or zone melting.

Convenience of operation

The large opening design facilitates robotic or manual operation and reduces the risk of sample contamination.

- Typical Cases

Directional solidification experiment

A rectangular alumina crucible is used to achieve directional solidification of metal alloys through wall thickness gradient design to prepare single crystal materials.

Semiconductor wafer preparation

Rectangular platinum crucibles are used for gallium arsenide (GaAs) single crystal growth. The cavity size matches the wafer size to improve material utilization.

Batch Metal Melting

Rectangular graphite crucible is used to melt titanium alloy in vacuum induction furnace, with a single processing capacity of 50kg , which significantly improves production efficiency.

- Selection Basis

Experimental requirements

When directional solidification or zone melting is required, a rectangular crucible with a gradient wall thickness should be selected.

When processing samples in batches, rectangular crucibles with large openings and large capacities are preferred.

Material matching

Graphite or molybdenum crucibles are used for high-temperature alloy smelting; platinum or quartz crucibles are used for high-purity experiments.

Cost and lifespan

Ceramic crucibles are low cost but short life; metal crucibles are high cost but reusable.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

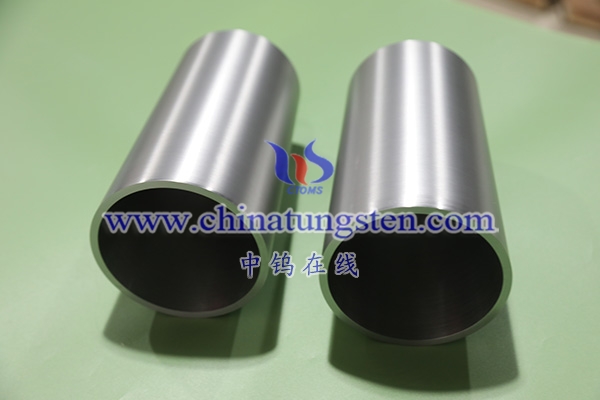

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595