A large crucible is an industrial equipment used to hold and heat a large amount of raw materials for melting, purification or chemical reaction. It is large in size and is usually used in high-temperature industrial fields such as metal smelting, ceramic manufacturing, and chemical experiments.

- Definition and Characteristics

Definition: A large crucible is a high temperature resistant container used to heat, melt or chemically react raw materials at high temperatures.

Features:

Large size: can hold a large amount of raw materials and is suitable for large-scale production.

High temperature resistance: Made of refractory materials (such as graphite, quartz, alumina, etc.), it can withstand extremely high temperatures.

Chemical stability: It is not easy to react chemically with molten materials at high temperatures, ensuring product purity.

- Application fields

Metal smelting: used to melt metals (such as steel, iron, copper, aluminum, etc.) for casting or alloy preparation.

Ceramic manufacturing: used for firing ceramic materials, such as high-temperature ceramics, electronic ceramics, etc.

Chemical experiments: used in laboratories for high-temperature reactions or material synthesis.

Semiconductor industry: used in the production of semiconductor materials such as single crystal silicon, such as the use of quartz crucibles in drawing silicon rods.

- Common types

Graphite Crucible:

Features: Good thermal conductivity and high temperature resistance, small thermal expansion coefficient, and certain resistance to strain from rapid heating and cooling.

Application: Widely used in metallurgy, casting, machinery, chemical industry and other industrial sectors.

Quartz crucible:

Features: high purity, strong temperature resistance, large size, high precision and good thermal insulation.

Application: It is used to pull large-diameter single-crystal silicon in the semiconductor industry and is an essential basic material for the development of large-scale integrated circuits.

Alumina crucible (corundum crucible):

Features: Alumina content exceeds 95%, hard and resistant to melting.

Application: Suitable for melting samples using some weak alkaline substances as flux.

Silicon carbide crucible:

Features: It can withstand higher temperatures than glassware and has good wear resistance.

Application: It has been widely used in industrial fields such as ceramics and glass.

- Manufacturing process

Isostatic pressing: Uniform pressure is transmitted through high-pressure liquid medium, so that the refractory raw materials are subjected to the same pressure in all directions, thus forming a crucible with high density, low porosity and high mechanical strength.

Sintering: The formed crucible needs to be sintered at high temperature to improve its refractory properties and mechanical strength.

- Advantages

Efficient production: Able to accommodate large amounts of raw materials and improve production efficiency.

Guaranteed purity: Good high temperature resistance and chemical stability to ensure the purity of the molten material.

Strong adaptability: It is not limited by production scale, batch size and smelting material types and can be selected arbitrarily.

- Notes

Safe operation: When operating large crucibles at high temperatures, safety regulations must be strictly followed to prevent burns or fire.

Regular maintenance: Cleaning and maintenance are required after use to extend the service life of the crucible.

Choose the right material: Choose the right crucible material according to the properties of the molten material to avoid chemical reactions or crucible damage.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

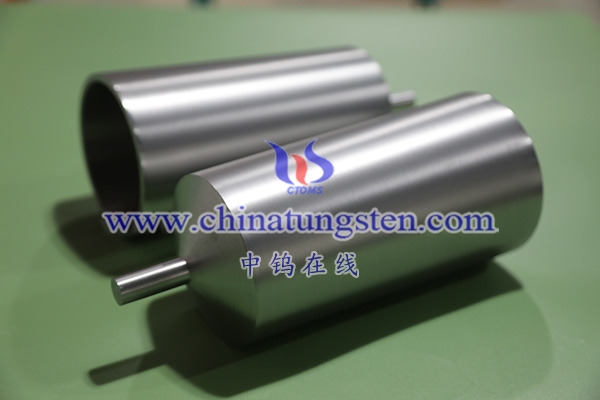

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595