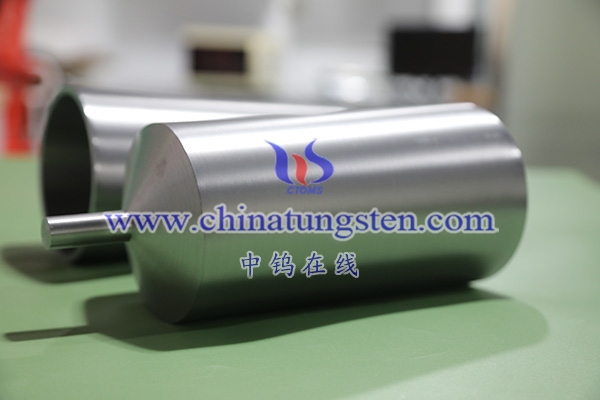

A polished crucible is a crucible that has been surface polished and is mainly used in high-temperature experiments or industrial production where high material purity is required.

Definition and characteristics

Polishing: The inner wall of the crucible is treated by mechanical or chemical methods to reduce its surface roughness and achieve a mirror or sub-mirror effect.

High purity requirements: Polishing can reduce residual impurities and avoid contamination caused by crucible surface defects during the experiment. It is suitable for experiments with extremely high requirements for material purity, such as semiconductor material preparation, high-purity metal smelting, etc.

High temperature resistance: Polishing crucibles are usually made of high melting point materials (such as quartz, alumina, graphite, etc.) and can withstand high temperature environments without deformation or chemical reactions.

Application Areas

Laboratory research: In experiments such as chemical analysis and material synthesis, polished crucibles can be used for high-temperature melting, crystal growth and other processes to ensure the accuracy of experimental results.

Industrial production: In metallurgy, ceramics, electronics and other industries, polished crucibles can be used for smelting and processing of high-purity materials, such as sapphire crystal growth, rare earth metal purification, etc.

Common materials

Quartz crucible: It has the characteristics of high purity, high temperature resistance, good chemical stability, etc., and is suitable for the preparation of semiconductor materials.

Alumina crucible: high temperature and corrosion resistant, suitable for high temperature chemical reactions and material smelting.

Graphite crucible: good thermal conductivity, high temperature resistance, suitable for metal smelting and carbide synthesis.

Polishing process

Mechanical polishing: Use sandpaper, polishing cloth and other tools to polish the crucible surface and gradually reduce the surface roughness.

Chemical polishing: The crucible surface is corroded by chemical reagents to remove microscopic defects and obtain a smooth surface.

Ultra-precision polishing: Combining mechanical and chemical methods to achieve nano-scale surface roughness, suitable for scenarios with ultra-high purity requirements.

Advantages

Reduce impurity contamination: Polishing the surface can reduce impurity adsorption and improve material purity.

Improve experimental accuracy: Smooth surface is conducive to uniform heat transfer, reducing local overheating or uneven reaction.

Prolong service life: Polishing can enhance the corrosion resistance and wear resistance of the crucible and prolong its service life.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595