The crucible can be welded by argon arc welding (TIG welding). This process forms an arc between the tungsten electrode and the workpiece, and uses inert gas argon to protect the molten pool to avoid oxidation. It is suitable for precision welding of high melting point metals such as molybdenum.

Specific welding process description

Welding Principle

Argon arc welding uses an arc generated between a non-melting tungsten electrode and the workpiece, melting the base material and filler metal through a high-energy density arc. At the same time, argon gas forms an inert gas protective layer to isolate the air and prevent oxidation and nitridation.

Process characteristics

Controllable heat input: By adjusting the current and welding speed, the heat input can be precisely controlled to avoid overheating and deformation of the molybdenum material.

High weld quality: Under argon protection, the weld is pure with few defects, suitable for molybdenum crucibles with high purity requirements.

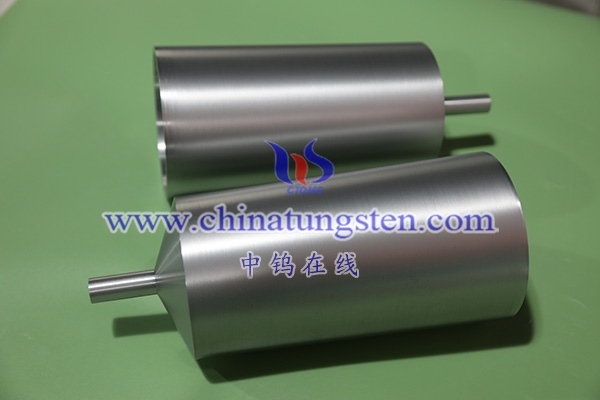

Strong applicability: It can weld molybdenum plates with a thickness of 0.5-4mm to meet the needs of crucibles of different specifications.

Key Parameters

Current: 80-400A (adjusted according to the thickness of the molybdenum plate).

Pressure control: Before welding, evacuate to -0.5 to -0.8MPa and fill with argon to a gauge pressure of -0.005 to 0MPa.

Heat treatment: Raise the temperature to about 1500℃ in stages to eliminate welding stress and improve microstructure uniformity.

Process advantages

Avoid oxidation: Argon protection effectively prevents molybdenum from oxidation at high temperatures and maintains the purity of the crucible.

Reduce impurities: No welding slag residue, reduce the introduction of impurities, and ensure the quality of crystal growth.

Strong adaptability: special-shaped structures can be welded to meet the manufacturing needs of crucibles with complex shapes.

Application Effect

The molybdenum crucible prepared by argon arc welding performed well in the crystal growth experiment, with a significantly reduced crucible leakage rate and improved crystal yield. For example, in one case, the crucible leakage rate of the welded molybdenum crucible was 0, and the crystal yield rate reached 49.3%, which is better than the traditional stamping process.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595