Molybdenum crucible usually needs to be annealed, which is a key step in the manufacturing process, aiming to eliminate processing stress, optimize organizational properties and increase service life. The following is an explanation of the necessity, process points and impact analysis of annealing:

- Necessity of annealing

Relieve processing stress

Molybdenum crucibles will generate internal stress during the forming process (such as powder metallurgy, forging, and welding). Annealing can release the stress and prevent cracking due to stress concentration during subsequent use.

Optimizing organizational performance

Annealing can adjust the grain structure of molybdenum, make it uniform, improve high-temperature strength and creep resistance, and adapt to high-temperature environments such as crystal growth.

Improve machining accuracy

After stress relief, the dimensional stability of the crucible is enhanced, which can reduce deformation in subsequent machining (such as turning and grinding).

- Annealing process points

Temperature control

Recommended temperature: 1200-1500℃ (the specific temperature needs to be adjusted according to the thickness and material of the crucible).

Heating rate: ≤100℃/h, to avoid cracking caused by thermal shock.

Holding time: 1-4 hours (proportional to the crucible size).

Cooling method

Furnace cooling: cooling rate ≤50℃/h to prevent abnormal grain growth.

Protective atmosphere: filled with argon or vacuum environment throughout the process to avoid oxidation.

Equipment selection

It is recommended to use a vacuum heat treatment furnace or an argon protection furnace to ensure the annealing quality.

- Effect of annealing on the performance of molybdenum crucible

| Performance index | Before annealing | After annealing | Improvement effect |

|–||–|-|

| Hardness | HV220 -260 | HV180 -220 | Reduce by 15%-25% |

| Tensile strength | 400- 500MPa | 350- 450MPa | Reduced by 5%-10% |

| Elongation | 5%-8% | 10%-15% | Increase 50%-100% |

| High temperature strength | Easy to deform after long-term use | Enhanced creep resistance | Improved stability |

- Precautions for annealing process

Avoid overburning

When the temperature exceeds 1600°C, the molybdenum grains will grow rapidly, resulting in increased brittleness, and the temperature needs to be strictly controlled.

Prevent oxidation

A protective atmosphere is required throughout the annealing process, otherwise molybdenum oxide (MoO ₃) will be generated on the molybdenum surface, affecting the purity.

Dimension monitoring

After annealing, the dimensional changes of the crucible need to be checked to ensure that the design tolerances are met (such as diameter deviation ≤ ± 0.1mm).

======================================================================

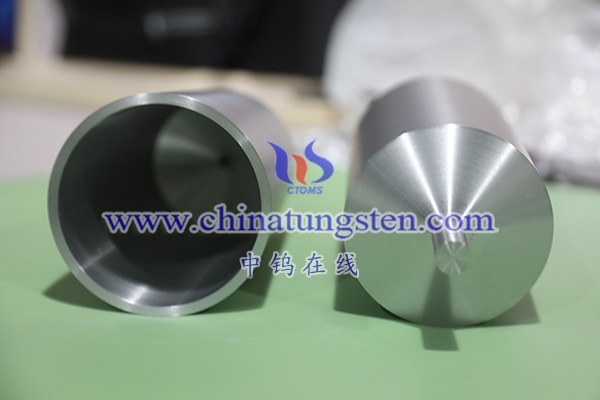

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595