To ensure the concentricity and wall thickness consistency of the molybdenum crucible, comprehensive control is required from the aspects of design, processing, welding, testing, etc. The following are specific measures and methods:

- Optimized design and mold manufacturing

Concentricity design

Use an integrated core mold (such as a graphite core mold) to ensure that the datum of the inner and outer walls is unified and to avoid the accumulation of errors in segmented processing.

The mold needs to be CNC precision machined with a surface roughness of ≤ Ra0.8 μm to ensure uniform crucible wall thickness.

Wall thickness control design

0.2-0.3mm is reserved during design, and the wall thickness is precisely controlled through subsequent mechanical processing (such as turning).

The equal wall thickness segmented design is adopted to avoid uneven thickness due to complex local structure.

- Processing technology control

Powder Metallurgy Forming

Using isostatic pressing technology, the pressure is ≥ 200MPa to ensure uniform density of molybdenum powder and reduce internal porosity and wall thickness deviation.

Strictly control the sintering temperature (1800-2000℃) and holding time to avoid uneven grain growth leading to different wall thickness.

Machining

Use CNC lathe for inner and outer wall processing, with cutting speed ≤ 20m /min and feed rate ≤ 0.1mm /rev to reduce vibration and deformation.

After processing, the wall thickness is tested and measured every 10° to ensure that the deviation is ≤± 0.05mm.

- Welding process optimization

TIG welding parameter control

Current: 80-150A (adjusted according to the thickness of the molybdenum plate) to avoid deformation caused by local overheating.

Welding speed: 5-10mm / s, ensuring uniform weld and minimal heat affected zone.

Heat treatment: Raise the temperature to 1500℃ in stages and keep it for 2 hours to eliminate welding stress and reduce concentricity deviation.

Welding sequence

Symmetrical welding is adopted, welding layer by layer from bottom to top to avoid the crucible tilting due to gravity.

- Testing and Quality Assurance

Concentricity detection

Use a three-coordinate measuring machine or laser scanner to detect the concentricity of the inner and outer walls, and the deviation is required to be ≤± 0.1mm.

The test must be carried out at room temperature (20±2℃) to avoid dimensional deviation caused by temperature changes.

Wall thickness detection

An ultrasonic thickness gauge is used to measure the wall thickness every 5° to ensure uniformity.

Perform X-ray inspection on the welding area to eliminate defects such as lack of fusion and cracks.

- Examples of key process parameters

| parameter | Recommended value | effect |

| Welding current | 80-150A | Control the depth of penetration to avoid burn-through |

| Welding speed | 5-10mm / s | Ensure uniformity of weld seam |

| Heat treatment temperature | 1500℃ | Eliminate stress and improve tissue uniformity |

| Wall thickness deviation | ≤± 0.05mm | Ensure structural stability |

| Concentricity deviation | ≤± 0.1mm | Ensure crucible rotation balance |

- Common Problems and Solutions

Concentricity deviation

Cause: mold wear and welding deformation.

Solution: Calibrate the mold regularly and use symmetrical welding process.

Uneven wall thickness

Cause: Uneven powder distribution and processing vibration.

Solution: Optimize the powder pressing process and increase the rigidity of the fixture.

the concentricity deviation of the molybdenum crucible can be controlled within ± 0.1mm, and the wall thickness deviation can be controlled within ± 0.05mm, meeting the high-precision requirements of crystal growth equipment for crucibles.

======================================================================

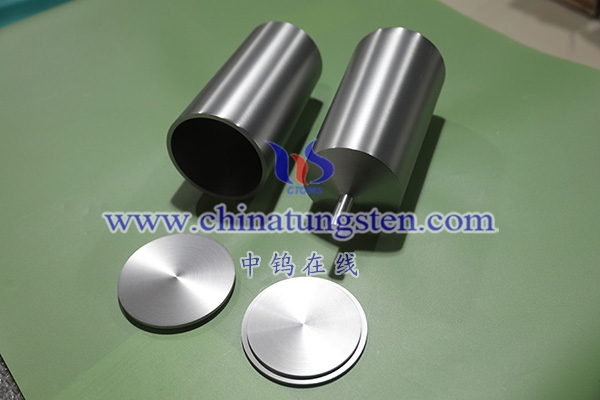

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595