Molybdenum crucibles must meet the following requirements:

- Molybdenum purity standard

Purity requirements: The molybdenum content of the molybdenum crucible must reach more than 99.95% (in line with ASTM B386 standard), and some high-end applications require a purity of 99.98%.

Trash element restrictions:

Impurities such as iron (Fe), nickel (Ni), and carbon (C) need to be controlled at the ppm level (e.g. Fe≤0.005%, Ni≤0.003%, C≤0.001%).

The content of elements such as lead (Pb), bismuth (Bi), tin (Sn), antimony (Sb), and cadmium (Cd) must be ≤ 0.0005%.

The content of impurities such as aluminum (Al) and silicon (Si) must be ≤ 0.005%.

- Process control standards

Powder metallurgy process:

Molybdenum powder needs to be sieved, combined and isostatically pressed to ensure that impurities are evenly distributed.

The medium frequency sintering temperature needs to be precisely controlled to avoid the infiltration of impurities such as carbon and oxygen.

Spinning process:

Spin forming needs to be carried out in a clean workshop to prevent contamination from environmental impurities.

The surface roughness must reach Ra≤3.2μm to reduce material sticking to the wall.

Surface treatment:

The inner wall is electropolished to Ra≤1.6μm, and the outer wall is sprayed with 0.1-0.3mm yttrium oxide thermal barrier coating to reduce radiation heat loss.

- Testing and verification standards

Impurity detection method:

The carbon content was measured by coulometric method, the oxygen content was measured by proton activation method, and the metal impurities were measured by spectral analysis method.

A material report is required to prove that the purity is ≥99.95% and the impurity content meets the standards.

Non-destructive testing:

Internal defects are checked by X-ray inspection to ensure that there are no impurity accumulation areas such as cracks and pores.

Sealing test:

Molybdenum crucibles with lids need to be tested for vacuum (e.g. ≤10 ⁻⁴ Pa) to ensure sealing.

- Application scenarios’ requirements for impurities

Crystal Growth:

Carbon and oxygen impurities must be strictly controlled to avoid the formation of compounds such as MoC that contaminate the melt.

Semiconductor Manufacturing:

It must meet high vacuum environment requirements and the impurity content must be less than 0.0001%.

Rare earth smelting:

It is necessary to reduce the Mo impurity content in rare earth metals. The use of F4200J -based alloy crucible can reduce the Mo impurity to 0.03%-0.05%.

- Industry standards and certification

National standards: Must comply with industry standards such as YS/T 1247-2018 (spinning molybdenum crucible).

International Certification: Passed ISO 9001 quality management system certification to ensure compliance with impurity control processes.

======================================================================

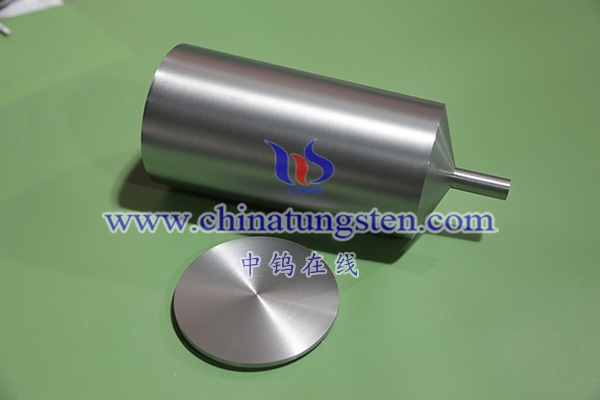

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595