Ultrasonic testing (UT) of molybdenum crucibles is an efficient and non-destructive testing method. It is mainly used to find defects such as cracks, inclusions, pores, delamination and loose structure inside the crucible. It is especially suitable for molybdenum, a metal with high density, difficult to process and used in high temperature environments.

- Why do molybdenum crucibles need ultrasonic testing?

Molybdenum crucibles are generally used in high-temperature smelting, single crystal furnaces, rare metal refining and other working conditions. If there are defects inside, it is easy to:

Explosion, leakage, and breakage occur;

Leading to furnace contamination and test failure;

Shorten life or cause safety accidents.

Therefore, ultrasonic flaw detection is an important means to detect its quality stability and safety reliability.

- Applicable ultrasonic flaw detection methods

| method | illustrate | Applicable types |

| Longitudinal wave flaw detection (L wave) | Ultrasonic wave is incident vertically to detect internal defect reflections | Suitable for cylindrical/thick-walled crucibles |

| Shear wave flaw detection (S wave) | Ultrasonic wave is incident obliquely, suitable for surface or near-surface defects | Thinner wall structures and welding parts |

| Immersion testing | Put the crucible into the water tank, the coupling is uniform and the signal is stable | Small size and high precision detection |

| Phased Array Ultrasound ( PAUT ) | Multi-beam scanning can achieve two-dimensional imaging | For advanced products or sophisticated evaluation |

- Testing process steps

Surface preparation:

Remove surface oil, scale and residue;

Polish or sand uneven areas;

Ensure good acoustic wave coupling.

Select couplant:

Generally, a special coupling agent, engine oil or glycerin aqueous solution is used;

Ensure the transmission of acoustic energy between the probe and the workpiece.

Device parameter settings:

Probe frequency: 2.5~10 MHz (commonly used is 5 MHz);

Probe type: straight probe (longitudinal wave) or oblique probe (transverse wave);

Gain, scanning speed, etc. are adjusted according to the crucible thickness and diameter.

Scanning method:

Longitudinal wave: scans vertically across the wall thickness from the bottom or top;

Shear wave: Scan obliquely from the outer side wall or weld;

Move in spiral or linearly point by point;

For larger crucibles, a robotic arm or automated equipment can be used.

Signal analysis and judgment:

Defect reflection signal position, amplitude, phase change, etc.

Combined with **DAC (distance-amplitude compensation curve) or TCG (time-base gain curve) ** for quantitative analysis;

Determine whether the defect level allowed by the customer/standard is exceeded.

- Common defect types and signal manifestations

| Defect Type | Back to the port characteristics | Possible sources |

| crack | Clear peak echo, narrow waveform | Cold working or welding residual stress |

| Pores | Weak and diffuse echo | Gas does not escape during smelting |

| Layering | Double or multi-peak reflection | Insufficient forging or cold welding |

| Inclusions | Irregular strong reflection | Impurity elements are not removed |

| Loose area | Scattered band, chaotic signal | The metallurgical structure is not dense |

- Related Standards Reference

GB/T 12604.1-2020 Nondestructive Testing Terminology Part 1: Ultrasonic Testing

《GB/T 11345-2023 Manual ultrasonic testing of metal welds》

《ASTM E114-20 : Standard Ultrasonic Terminology》

Internal enterprise standards or customer technical agreements

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

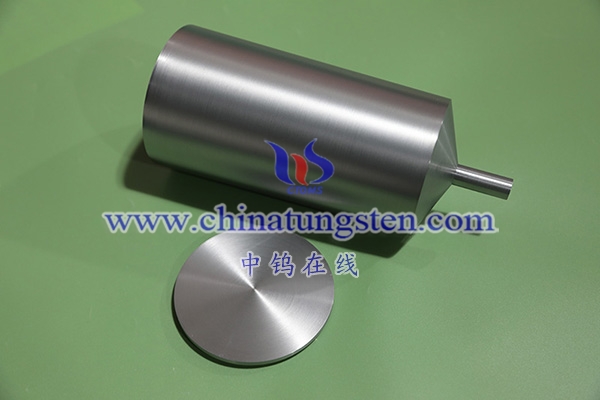

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595