Molybdenum crucibles may indeed produce cracks during processing, but they can be effectively controlled by optimizing the process and parameters. The following is a specific analysis:

- Common causes of cracks in molybdenum crucible processing

Material properties

Molybdenum has a high melting point (2623°C), but is significantly brittle at low temperatures and is prone to cracking due to stress concentration during processing.

Impurities (such as C, O) will reduce the ductility of molybdenum and increase the risk of cracking.

Processing Technology

Spin forming: If the feed speed is too fast or the lubrication is insufficient, it may cause surface tearing.

Welding: If the heat input is not properly controlled during electron beam welding ( EBW ) or laser welding, thermal cracks are likely to occur.

Machining: Excessive cutting force during turning and drilling may cause cracks.

Heat Treatment

Too high sintering temperature or too fast cooling speed will cause internal residual stress and induce cracks.

- Key technologies for crack control

Material selection

Use high purity molybdenum (≥99.95%) to reduce the impact of impurities on ductility.

Adding rare earth elements (such as lanthanum and cerium) improves toughness and reduces crack sensitivity.

Process Optimization

Spinning:

Control feed speed (≤0.1 mm/rev) and use graphite emulsion lubrication.

Spinning in sections to avoid excessive deformation in a single operation.

welding:

Use low heat input welding processes (such as electron beam welding) and preheat to 300-500℃ to reduce stress.

After welding, vacuum annealing (1000-1200℃, 2 hours) is performed to eliminate residual stress.

Machining:

Use carbide tools to reduce cutting forces.

Use small feed (≤0.05 mm/rev) and low cutting speed (≤50 m/min).

Heat Treatment

After sintering, homogenization annealing (1500-1800℃, 4 hours) is carried out to eliminate grain boundary segregation.

Control the cooling rate (≤10℃/min) to avoid cracks caused by rapid cooling.

- Crack Detection and Repair

Detection Methods

Nondestructive testing: X-ray testing and ultrasonic testing can detect internal cracks.

Visual inspection: Observe surface microcracks with a high-power magnifying glass.

Restoration Technology

Laser cladding: Local cladding of cracked areas to repair cracks and enhance surface properties.

Molybdenum wire of the same material as the base material for repair welding, and perform heat treatment after welding.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

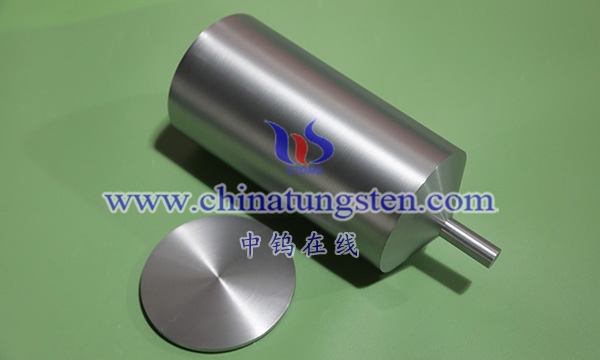

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595