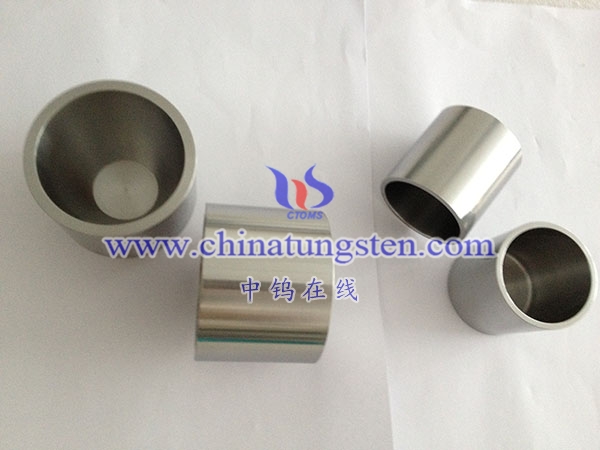

Molybdenum crucible refers to the process of deforming, cutting or forming molybdenum materials without heating or only slightly heating to obtain the required size, shape or surface accuracy. Since molybdenum has the characteristics of high strength, low plasticity and easy brittle fracture at room temperature, cold working is difficult, but it is very important for improving dimensional accuracy, finishing shape and repairing details, and is widely used in the post-processing stage of molybdenum crucible.

- Main cold working processes

- Cold Forging

Suitable for preforming of small-sized molybdenum crucibles;

Generally, mechanical punching machine or hydraulic press is used to cold press the mold under pressure;

the density and strength of the bottom or wall of the crucible;

However, the forming deformation needs to be strictly controlled to avoid micro cracks.

- Cold Rolling/Drawing

Mostly used for pre-processing of molybdenum tubes or molybdenum cylinders;

The ideal size can be obtained by gradually reducing the wall thickness and controlling the diameter;

Annealing is required in time after processing, otherwise the material will be too brittle to continue to deform.

- Machining

Turning, milling, drilling, boring, threading, etc.;

Used to form the flange, outer edge, mounting hole, positioning groove and other structures of the molybdenum crucible;

Carbide tools or diamond tools are required;

The cutting speed is low, the feed rate is moderate, and dry cutting or light lubrication is usually used.

- Grinding and polishing

Inner wall and outer surface finishing and precision improvement;

Use high temperature resistant abrasives such as aluminum oxide and silicon carbide;

Mirror polishing can be performed in situations where high precision is required (accuracy can reach Ra ≤ 0.2 μm);

It can be assisted by electrolytic polishing/ultrasonic polishing.

- Cold Spinning

Suitable for finishing of thin-walled molybdenum crucibles or head parts;

Complex geometric surfaces can be spun out by rollers at room temperature or slightly heated.

Processing should be slow and even to avoid cracked edges or wrinkles.

- Cold Straightening

Used to eliminate the warping and deformation of crucible after welding and sintering;

Use pressure correction, hydraulic shaping, vibration shaping and other methods;

It is often used in conjunction with nondestructive testing to ensure geometric accuracy and structural integrity.

- Difficulties and precautions of cold processing

| difficulty | reason | Countermeasures |

| Easy to crack | Molybdenum is brittle at room temperature. | Moderate preheating or annealing before processing |

| Fast tool wear | High hardness and high melting point | Select wear-resistant tools and control cutting parameters |

| Processed surface is easily scratched | Molybdenum surface is hard but brittle | Reduce feed and use fine-ground tools |

| High stress after deformation | Cold working accumulated stress | Annealing treatment is recommended after processing |

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595