In the manufacturing process of molybdenum crucibles, preventing oxidation is a key link to ensure material performance and product quality. The following systematically explains the specific measures to prevent oxidation from three dimensions: process design, environmental control and post-processing:

- Process design stage

- Powder metallurgy process optimization

Raw material selection: Use high-purity molybdenum powder (≥99.95%) to reduce oxidation catalysis caused by impurities (such as Fe, Ni).

Molding protection:

Cold isostatic pressing: carried out under the protection of inert gas (such as argon) to avoid powder oxidation.

Rubber sheath seal: prevents oxygen from penetrating during the molding process.

Sintering environment: Vacuum sintering (vacuum degree ≤ 10 ⁻ ³ Pa) or hydrogen protection sintering (H ₂ purity ≥ 99.999%) is used to inhibit the formation of MoO ₃.

- Machining protection

Tool selection: Use carbide tools (such as K10 / K20) or CBN tools to avoid the reaction between the tool and molybdenum at high temperatures.

Coolant: Use oil-based cutting fluid or emulsion to reduce cutting temperature and prevent oxidation.

Processing environment: Process in argon atmosphere to reduce air contact.

- Environmental Control

- Inert gas protection

Application scenarios:

The entire process of powder processing, molding, sintering and machining.

Argon purity: ≥99.996%, dew point ≤-60℃ (to prevent moisture from causing oxidation).

Equipment: Equipped with a gas circulation system and an oxygen content monitor (real-time display of O₂ content ≤10 ppm).

- Vacuum environment

Sintering furnace: Use vacuum hot pressing furnace or hot isostatic pressing furnace, and the vacuum degree must be stable at 10 ⁻ ³ ~10 ⁻⁵ Pa.

Inspection: Calibrate the vacuum gauge regularly to ensure that the vacuum degree meets the standard.

- Post-processing and packaging

- Surface passivation treatment

method:

Chemical passivation: Soak in dilute hydrochloric acid (10%) or hydrofluoric acid (5%) for a short time to remove the surface oxide layer.

Electrochemical passivation: Anodic oxidation is carried out in a phosphate solution to form a dense oxide film (thickness ≤ 1μm).

Effect: Significantly reduce surface activity and slow down oxidation rate.

- Anti-oxidation coating

Coating Material:

Molybdenum carbide /nitride (such as Mo₂C, MoN): prepared by physical vapor deposition (PVD) or chemical vapor deposition (CVD).

Ceramic coating (such as Al₂O₃, ZrO₂): resistant to high temperatures (≥1800℃) and isolated from oxygen.

Thickness: 5-20μm, ensuring the coating is dense and free of pores.

- Vacuum packaging

Packaging Materials:

Aluminum foil composite film: vacuumized and heat-sealed to isolate oxygen and moisture.

Glass/ceramic sealed jar: built-in desiccant (such as molecular sieve) for long-term storage.

Detection: After packaging, helium mass spectrometry leak detection is performed to ensure that the leak rate is ≤ 10 ⁻⁹ Pa · m ³ /s.

- Typical application cases

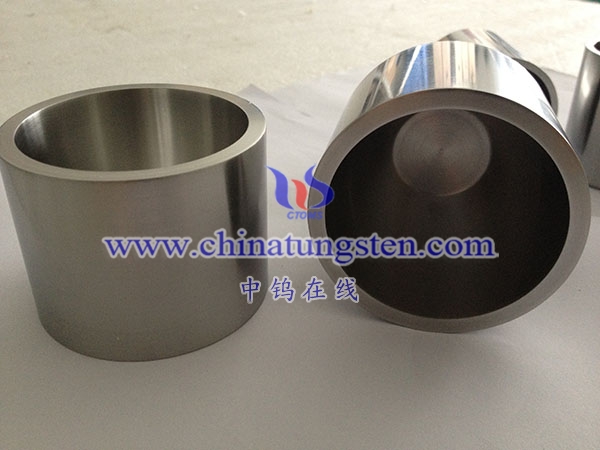

Molybdenum crucible for sapphire single crystal growth furnace

Process Control:

Powder purity ≥ 99.98%, sintering temperature 1900-2100℃ (vacuum degree 10 ⁻³ Pa).

Surface roughness Ra≤0.4μm, coating thickness 10μm.

Performance: Service life ≥ 100 times, oxidation weight gain ≤ 0.1wt %.

Molybdenum crucible for nuclear fusion device

Process Control:

Powder particle size D50 = 2-5μm, density after sintering ≥ 98%.

The coating adopts Mo₂C +ZrO₂ composite layer, and the thermal shock resistance is ≥10 cycles.

Performance: Oxidation rate ≤ 0.01mg /cm²·h at 1200℃.

- Notes

Operation Specifications:

Avoid direct contact between molybdenum products and oxygen-containing tools (such as alumina crucibles).

Wear rubber gloves when handling powder to prevent oxidation caused by sweat.

Equipment maintenance:

Clean the inner wall of the sintering furnace regularly to remove residual oxides.

Check the vacuum pump oil level to prevent oil vapor contamination.

Quality Inspection:

The oxygen content of raw materials is tested when they enter the factory ( ICP -OES method).

Finished product testing must include oxidation weight gain test (1000℃/ 24h ) and metallographic analysis.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595