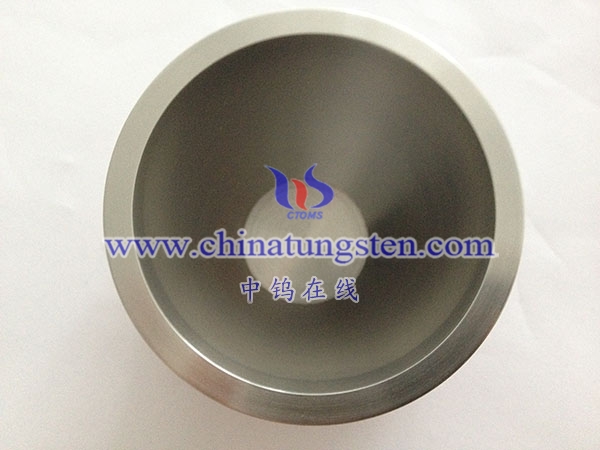

Molybdenum crucible plays a key role in material support and process guarantee in semiconductor manufacturing, especially in extreme environments such as high temperature, high vacuum and chemical corrosion, where their performance directly determines the quality and reliability of semiconductor devices. The following is a detailed description from three aspects: core functions, technical advantages and application scenarios:

- Core Functions

High temperature material melting and purification

Function: Used to smelt high- purity metals (such as tungsten, molybdenum, tantalum, etc.) and compounds (such as silicide, nitride) to provide ultra-high purity source materials for semiconductor thin film deposition.

Advantages: Molybdenum crucible has a high melting point (2610°C) and high temperature oxidation resistance, can withstand extreme temperatures above 2000°C, and avoid the introduction of impurities.

Core components of the thermal field of the single crystal growth furnace

Function: As the thermal field component of the growth furnace of sapphire single crystal, silicon carbide single crystal, etc., it carries the melt and maintains the temperature gradient.

Advantages: Molybdenum ’s low coefficient of thermal expansion (5.5×10⁻⁶ / ° C) and high thermal conductivity ensure temperature uniformity and reduce crystal defects.

Chemical Vapor Deposition (CVD) Reactor Chamber

Function: As a reaction vessel for CVD equipment, it carries high-temperature gas reactions and deposits thin film materials (such as gallium nitride and hafnium oxide).

Advantages: The chemical inertness of molybdenum prevents reaction with reactive gases and ensures the purity of the film.

- Technical advantages

| Performance Indicators | Molybdenum crucible characteristics | Contribution to semiconductor manufacturing |

| purity | ≥99.95% | Avoid metal impurity contamination and improve device yield |

| High temperature stability | 2610℃ melting point, 2000℃ long-term use | Meet the requirements of high temperature processes such as epitaxial growth and annealing |

| Thermal expansion matching | to SiC (4.4×10 ⁻⁶ / ℃) | Reduce thermal stress and avoid thermal shock cracking |

| Corrosion resistance | Molten metal corrosion resistance | Suitable for metal smelting and chemically corrosive environments |

| Mechanical strength | Tensile strength ≥ 600MPa | Withstand thermal pressure and mechanical vibration |

- Application Scenarios

Power semiconductor devices

Application: Epitaxial growth of silicon carbide (SiC) power devices.

Requirements: Molybdenum crucibles need to withstand temperatures above 2000°C to maintain the temperature gradient of the SiC melt and ensure the uniformity of the epitaxial layer.

Optoelectronic devices

Application: Sapphire-based LED chip manufacturing.

Demand: As a thermal field component of a single crystal growth furnace, molybdenum crucibles must have high purity and low thermal expansion properties to reduce crystal dislocations.

Advanced Packaging

Application: melting of tungsten-copper alloy bonding materials.

Requirements: Molybdenum crucibles need to be resistant to high temperature oxidation to avoid the introduction of oxygen impurities that affect the bonding strength.

- Case Comparison

| Application Areas | Traditional Materials | Molybdenum crucible advantages | Typical indicator improvement |

| SiC epitaxial growth | Graphite Crucible | High temperature oxidation resistance, low thermal expansion, high purity | Crystal defect density reduced by 30%, yield increased by 15% |

| Sapphire single crystal growth | Tungsten Crucible | Lower cost and better processability | Crystal diameter expanded to 8 inches, cost reduced by 20% |

| Metal smelting | Alumina Crucible | Resistant to molten metal corrosion, high strength at high temperature | Metal purity increased to 99.9999% |

- Technical Challenges and Solutions

Oxidation Problem

Challenge: At high temperatures, the molybdenum surface oxidizes to generate MoO₃, which volatilizes and causes material loss.

Solution:

Surface coating technology (such as Mo₂C, ZrO₂ coating);

Vacuum or inert gas (such as Ar) protection.

Mechanical deformation

Challenge: Long-term high-temperature use causes the crucible to deform, affecting the uniformity of the thermal field.

Solution:

Optimize the crucible structure design (such as adding reinforcing ribs);

with high density (≥ 10.2g /cm³) molybdenum powder.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595