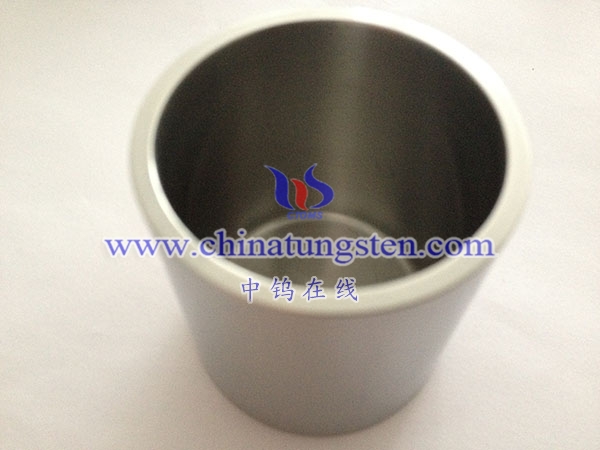

Molybdenum crucibles are suitable for glass melting, especially in high temperature, high purity and special process requirements. The following is a detailed description of the applicability principle, technical advantages and application scenarios:

- Applicability principle

High temperature resistance

molybdenum is as high as 2610℃. The molybdenum crucible can work stably at high temperatures above 2000℃, meeting the melting requirements of high-melting-point glasses such as quartz glass (melting point is about 1713℃).

During the glass melting process, the molybdenum crucible can withstand high temperatures for a long time without deformation or melting, ensuring process stability.

Chemical stability

Molybdenum does not chemically react with glass melts (such as silicates, borates, etc.) at high temperatures, thus avoiding the introduction of impurities and ensuring the purity and optical properties of the glass.

Especially in the fields of optical glass, optical fiber preforms, etc. which have extremely high requirements on purity, the chemical inertness of molybdenum crucible is very important.

Thermal conductivity

Molybdenum has high thermal conductivity (about 138 W/(m·K)), which can conduct heat quickly and evenly, reduce the temperature gradient in the glass melt, and avoid glass defects (such as bubbles and streaks) caused by local overheating.

- Technical advantages

High purity guarantee

Molybdenum crucibles are made of high-purity molybdenum powder (≥99.95%) to avoid metal impurities contaminating the glass melt and meet the purity requirements of high-end glass (such as optical glass and semiconductor glass).

Thermal shock resistance

Molybdenum ‘s low thermal expansion coefficient (about 5.5×10 ⁻⁶ / ℃) makes it excellent in thermal shock resistance during high-temperature melting and cooling, reducing the risk of cracking due to thermal stress.

Mechanical strength

Molybdenum crucible has high strength and hardness, can withstand the mechanical impact and pressure in the glass melting process, and prolong its service life.

- Application Scenarios

Quartz glass melting

The melting of quartz glass (melting point 1713℃) needs to be carried out at a high temperature above 2000℃, and molybdenum crucible is the core container in this field.

For example, China’s quartz glass production requires about 25 molybdenum crucibles and consumes about 6 tons of molybdenum materials each year.

Optical glass manufacturing

In the production of optical glass (such as borosilicate glass), molybdenum crucibles are used to melt high- purity raw materials to ensure the light transmittance and uniformity of the glass.

Special glass research and development

In the research and development of special glasses such as optical fiber preforms and semiconductor glass, molybdenum crucibles provide a high-temperature, pure melting environment to promote material innovation.

- Cases and Data Support

Quartz glass melting: Molybdenum crucible is used as the core container in the quartz glass melting furnace. The annual demand is stable, which verifies its reliability in high-temperature glass melting.

Purity of optical glass: The impurity content of optical glass melted in molybdenum crucible can be controlled at ppm level to meet the needs of high-end applications.

thermal shock performance: Compared with graphite crucibles, the cracking rate of molybdenum crucibles during high-temperature rapid cooling is reduced by more than 50%, significantly improving production efficiency.

- Notes

Oxidation protection

In a high-temperature oxidizing environment, volatile MoO₃ is easily generated on the molybdenum surface, resulting in material loss. It needs to be used under vacuum or inert gas (such as Ar) protection.

Surface coating technology (such as Mo₂C and ZrO₂ coating) can effectively delay oxidation.

Cost and lifespan

Molybdenum crucibles cost more than traditional crucibles (such as graphite, alumina), but their long life (about 30-80 heats) and low maintenance cost make them more economical in high-end applications.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595