Molybdenum crucibles can be used for silicon smelting in the solar industry, especially in key links such as single crystal silicon growth and polycrystalline silicon ingot casting. The following is a specific analysis:

- The core advantages of molybdenum crucible in silicon smelting

High temperature resistance: The melting point of molybdenum is as high as 2610℃. The molybdenum crucible can work stably in a high temperature environment above 2000℃, meeting the needs of silicon smelting (about 1414℃) and crystal growth (such as the Czochralski method single crystal silicon growth temperature is about 1450℃).

Chemical inertness: Molybdenum does not react chemically with silicon at high temperatures, thus avoiding the introduction of impurities and ensuring the purity of the silicon material.

Low thermal expansion coefficient: The thermal expansion coefficient of molybdenum (about 5.5×10 ⁻⁶ / ℃ ) is similar to that of silicon, which reduces cracking or deformation caused by thermal stress and improves the quality of crystal growth.

High thermal conductivity: Molybdenum has excellent thermal conductivity, which can quickly and evenly conduct heat, reduce temperature gradients, and improve the uniformity and yield of crystal growth.

- Specific applications in the solar industry

Single crystal silicon growth:

the Czochralski method of single crystal silicon growth, the molybdenum crucible serves as the core container, carrying molten silicon and withstanding high temperature environments. Its high purity and chemical stability can avoid impurity contamination and ensure the electrical properties of single crystal silicon.

Polysilicon Ingot:

In the polysilicon ingot casting process, molybdenum crucibles are used to melt high- purity silicon materials. Their corrosion resistance ensures the purity of silicon ingots and improves the conversion efficiency of solar cells.

Quartz crucible alternative:

Although quartz crucibles are the traditional choice, molybdenum crucibles have more advantages in high temperature stability, mechanical strength and life, and are especially suitable for high-end single crystal silicon production.

- Technical parameters and case support

Operating temperature range: The operating temperature of molybdenum crucible is usually between 1100℃ and 1800℃, covering the temperature range of silicon melting and crystal growth.

Purity requirements: High-purity molybdenum (Mo≥99.95%) can avoid the introduction of impurities and meet the purity standards of solar-grade silicon (6N~9N).

Actual case:

In sapphire single crystal growth furnaces, molybdenum crucibles have been successfully used in high-temperature environments, and their performance can be transferred to the field of silicon smelting. For example, molybdenum crucibles can work continuously for thousands of hours in single crystal silicon growth furnaces, significantly reducing production costs.

- Notes

Oxidation protection: In air or oxygen environment, molybdenum is easily oxidized to generate volatile MoO ₃ and needs to be used under vacuum or inert gas (such as argon) protection.

Cost and life: Molybdenum crucibles cost more than traditional crucibles (such as quartz, graphite), but their long life (about 30-80 heats) and low maintenance cost make them more economical in high-end applications.

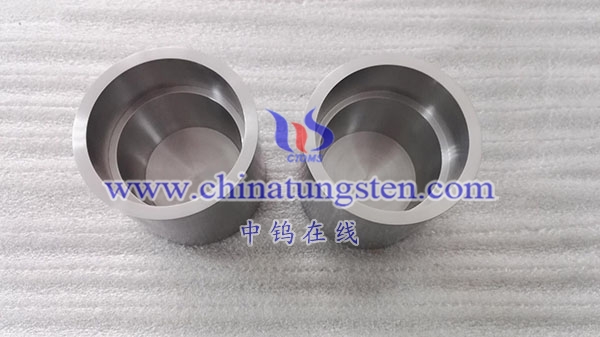

Mechanical processing: Molybdenum crucibles are difficult to process and require precision processing technology (such as spinning and sintering) to ensure dimensional accuracy and surface finish.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595