Molybdenum crucibles are mainly used in the vacuum evaporation process of organic materials and metal electrodes in the manufacturing process of OLED (organic light-emitting diodes). In this core link, molybdenum crucibles become one of the key heating containers due to their excellent high-temperature performance, purity and stability. The following is an analysis of its specific applications:

- The core process of OLED manufacturing: vacuum evaporation

The structure of OLED devices includes multiple organic light-emitting layers, charge transport layers, electrodes, etc. These functional layers are usually deposited by vacuum thermal evaporation (VTE):

Vacuum evaporation requires heating and sublimating small organic molecule materials under high vacuum (10 ⁻⁶ ~10 ⁻⁷ Torr);

The same method is also used to evaporate metal electrodes such as aluminum, silver, calcium, and magnesium.

In this process, a molybdenum crucible is used to hold these evaporation materials and heat them at high temperatures to sublimate or melt them, so that they are deposited on the substrate surface in a vacuum to form a uniform film.

- Advantages of molybdenum crucible and its manifestation in OLED:

- High melting point, suitable for heating high boiling point materials

Molybdenum has a melting point of up to 3410°C, making it suitable for evaporating various high-boiling-point organic molecules and metals (such as Al, Ag, Mo, etc.) without deformation or corrosion.

- High purity to avoid material contamination

Molybdenum materials have extremely high chemical purity (generally >99.95%) and will not release impurities or react during the vacuum evaporation process, thus ensuring the high purity and performance consistency of the thin film layer in the OLED device.

- Good thermal stability and uniform heat conduction

Molybdenum has excellent thermal conductivity and thermal stability, which can make the evaporation material heat more evenly and help form a flat functional film layer with uniform thickness.

- Resistant to vacuum environment and thermal stress

Molybdenum crucibles have excellent stability in high vacuum and high temperature rapid heating-cooling cycles, are not prone to cracking and deformation, and are suitable for continuous evaporation processes in large-scale OLED production lines.

- Typical application scenarios in OLED manufacturing:

- Evaporation of organic light-emitting materials

organic small molecule materials (such as Alq ₃, Ir ( ppy ) ₃, CBP, TPD, etc.) are heated and sublimated, they need to be heated stably within the temperature range of 200~400°C, and the molybdenum crucible is responsible for providing a uniform heat source.

- Evaporation of metal electrode materials

Metals used for anodes or cathodes (such as Al, Ca, Mg, Ag, Mo, Cu, etc.) require higher temperature heating. Molybdenum crucibles can meet the melting point requirements of these metals and avoid reactions with evaporation materials.

- Use with electron beam evaporation source

In some OLED processes, molybdenum crucibles are used as the liner of the electron beam evaporation source (e-beam crucible liner) for fine evaporation control of materials under higher energy conditions.

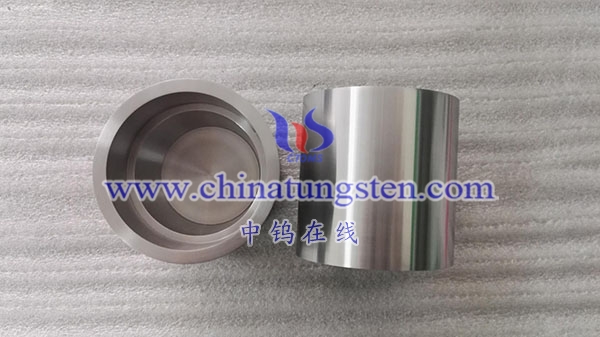

- Shape and specifications of molybdenum crucible:

molybdenum crucibles used in OLED devices include:

Cylindrical crucible: suitable for evaporation of larger amounts of material;

Boat-shaped molybdenum boat: suitable for evaporation of small batches and precision materials, widely used in laboratory OLED research and development;

Customized multi-cavity molybdenum crucible: meets the production needs of multi-layer simultaneous evaporation.

These crucibles often need to be polished, degassed, and dimensionally precision machined to ensure evaporation uniformity and compatibility with the vacuum system.

======================================================================

Customized R&D and Production of Tungsten, Molybdenum Products

Chinatungsten Online and CTIA GROUP LTD have been working in the tungsten industry for nearly 30 years, specializing in flexible customization of tungsten and molybdenum products worldwide, which are tungsten and molybdenum design, R&D, production, and overall solution integrators with high visibility and credibility worldwide.

Chinatungsten Online and CTIA GROUP LTD provide products mainly including: tungsten oxide products, such as tungstates such as APT/WO3; tungsten powder and tungsten carbide powder; tungsten metal products such as tungsten wire, tungsten ball, tungsten bar, tungsten electrode, etc.; high-density alloy products, such as dart rods, fishing sinkers, automotive tungsten crankshaft counterweights, mobile phones, clocks and watches, tungsten alloy shielding materials for radioactive medical equipment, etc.; tungsten silver and tungsten copper products for electronic appliances. Cemented carbide products include cutting tools such as cutting, grinding, milling, drilling, planing, wear-resistant parts, nozzles, spheres, anti-skid spikes, molds, structural parts, seals, bearings, high-pressure and high-temperature resistant cavities, top hammers, and other standard and customized high-hardness, high-strength, strong acid and alkali resistant high-performance products. Molybdenum products include molybdenum oxide, molybdenum powder, molybdenum and alloy sintering materials, molybdenum crucibles, molybdenum boats, TZM, TZC, molybdenum wires, molybdenum heating belts, molybdenum spouts, molybdenum copper, molybdenum tungsten alloys, molybdenum sputtering targets, sapphire single crystal furnace components, etc.

If you are interested in related products, please contact us:

Email: sales@chinatungsten.com

Tel: +86 592 5129696 / 86 592 5129595